Non-destructive particle suction extraction according to VDA 19.1

Dry, gentle on the material, standard-compliant - for reproducible cleanliness tests directly on the component or in the process.

Particle extraction is carried out by extracting dry adhering particles from component surfaces or from specific inspection areas. For this purpose, the particles are loosened from the surface and extracted using a suction nozzle, brush nozzle or surface nozzle. They are then specifically collected or deposited on

sample carriers such as laboratory bottles, analysis filters or particle traps.

In the world of technical cleanliness, wet extraction has been the state of the art for years. However, components that can be damaged by suction, dissolution etc. in contact with liquid media can only be tested to a limited extent with wet extraction. The previous "air extraction" by blowing off in a closed cabinet is now also reaching its limits with the greatly changed range of components in connection with e-mobility. Large and unwieldy components, such as battery trays, can no longer be extracted in a closed cabinet. The demand for testing methods directly in the process environment cannot be met with the established methods either.

CleanControlling therefore developed the suction extraction process some time ago. This was included in the new 2025 edition of VDA 19.1 as (brush) suction extraction. This method is a variant of "dry extraction" and is comprehensively described in the new VDA 19.1 with regard to the test parameters, the qualification of the test through to the light-optical analysis. Suction extraction is characterized in particular by its independence from closed test rooms and its mobile use.

Advantages of suction extraction

- Non-destructive testing (air / ESD protection) enables the component to be reused after testing

- Location-independent application for particle monitoring in the line

- Simple testing of large-area components thanks to the flexible testing system

- Selective testing possible without masking areas

- Application-oriented testing of components that must not be exposed to liquid media

- Reduced operating and logistics costs for component testing in the process environment and elimination of liquid extraction media

Effectiveness of suction extraction

Indirekte Prüfung

The determination of particle contamination resulting mainly from the manufacturing process is carried out by indirect testing. Before microscopic evaluation by measuring, counting and typing the particles, they are extracted from the component in a sampling step. This extraction is carried out with a liquid or dry medium.

The main extraction methods include

Pressure-rinsing

Air jet

Suction

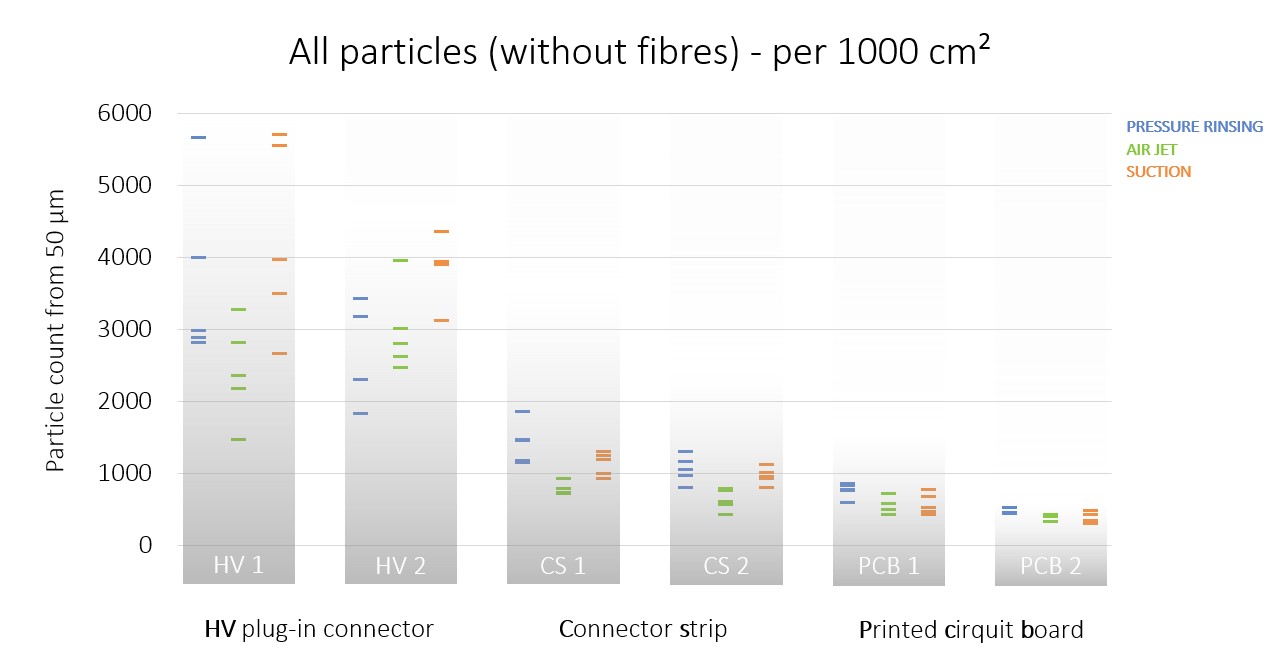

To investigate the effectiveness of these three extraction methods, a comprehensive study with a large-scale test series with various electrical and electronic assemblies was carried out in 2021 by a working group of the ZVEI e.V. (German Electrical and Electronic Manufacturers' Association). Several components of HV connectors, connector strips and printed circuit boards were taken from the same production batches and tested and analyzed using these three extraction methods. The focus here was on the total number of particles from several individual analyses and the scattering width between them.

The evaluation showed that the largest metallic particles are reliably extracted by all three methods examined. The results also show that although components from the same batch have a large scatter, this follows a normal distribution sufficiently to be able to derive mean values and standard deviations.

Statistical evaluation of effectiveness

The statistical analysis shows that the procedures are comparable.

Conclusion of the study

All extraction methods are suitable and comparable for determining the surface cleanliness of electronic components. On the one hand due to the reliable extraction of the largest particles and on the other hand due to the good correlation between the methods.

Suction extraction in action - Application videos

Detailed application videos about the structure, blank value, the various types of use and cleaning of the C|PS² particle suction extraction system can be found here:

Newsletter registration