Methods of particle separation

Versatile application according to VDA 19.1

The new VDA 19.1 describes the relevant start parameters for the test. These parameters are used to work out the final test parameters by means of a qualification test (decay measurement). In addition to the inlet area of the nozzle (2.0 cm²), the suction volume flow (≥ 20 m³/h) and the suction distance (max. 8 mm), the suction time per component area is defined. It can either be calculated using a formula or taken from the table or diagram in chapter 6.5.3 of VDA 19.1.

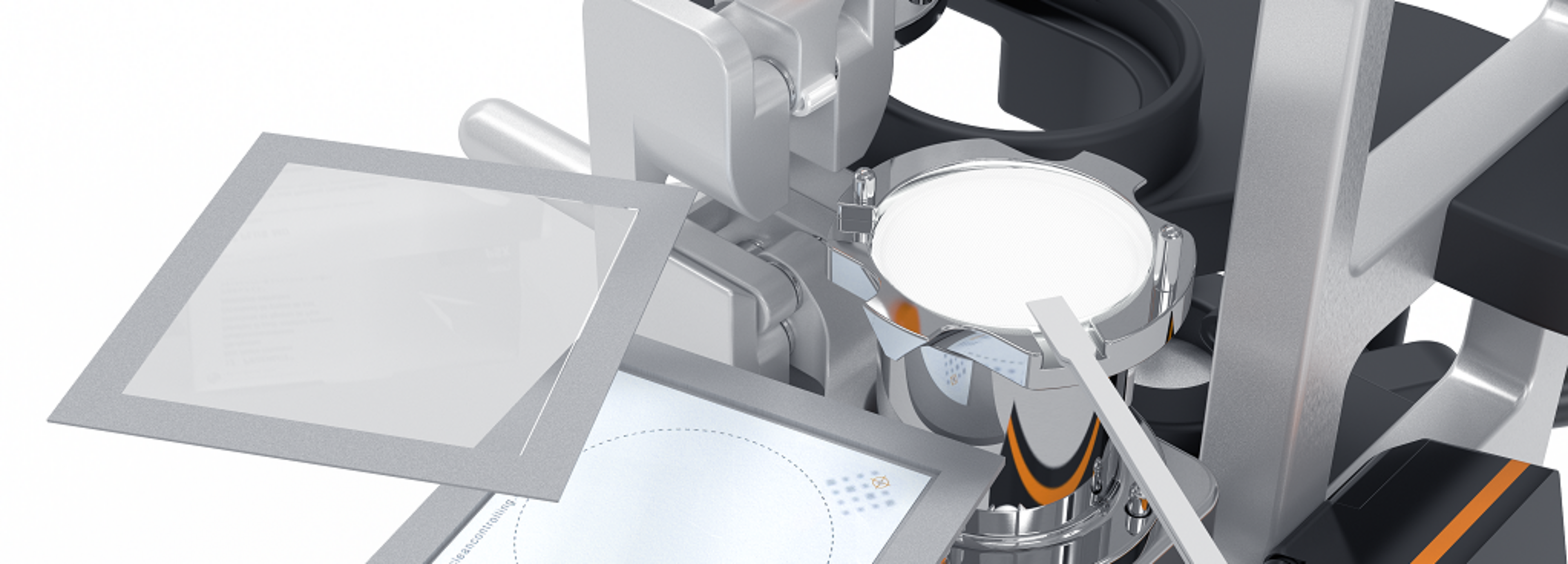

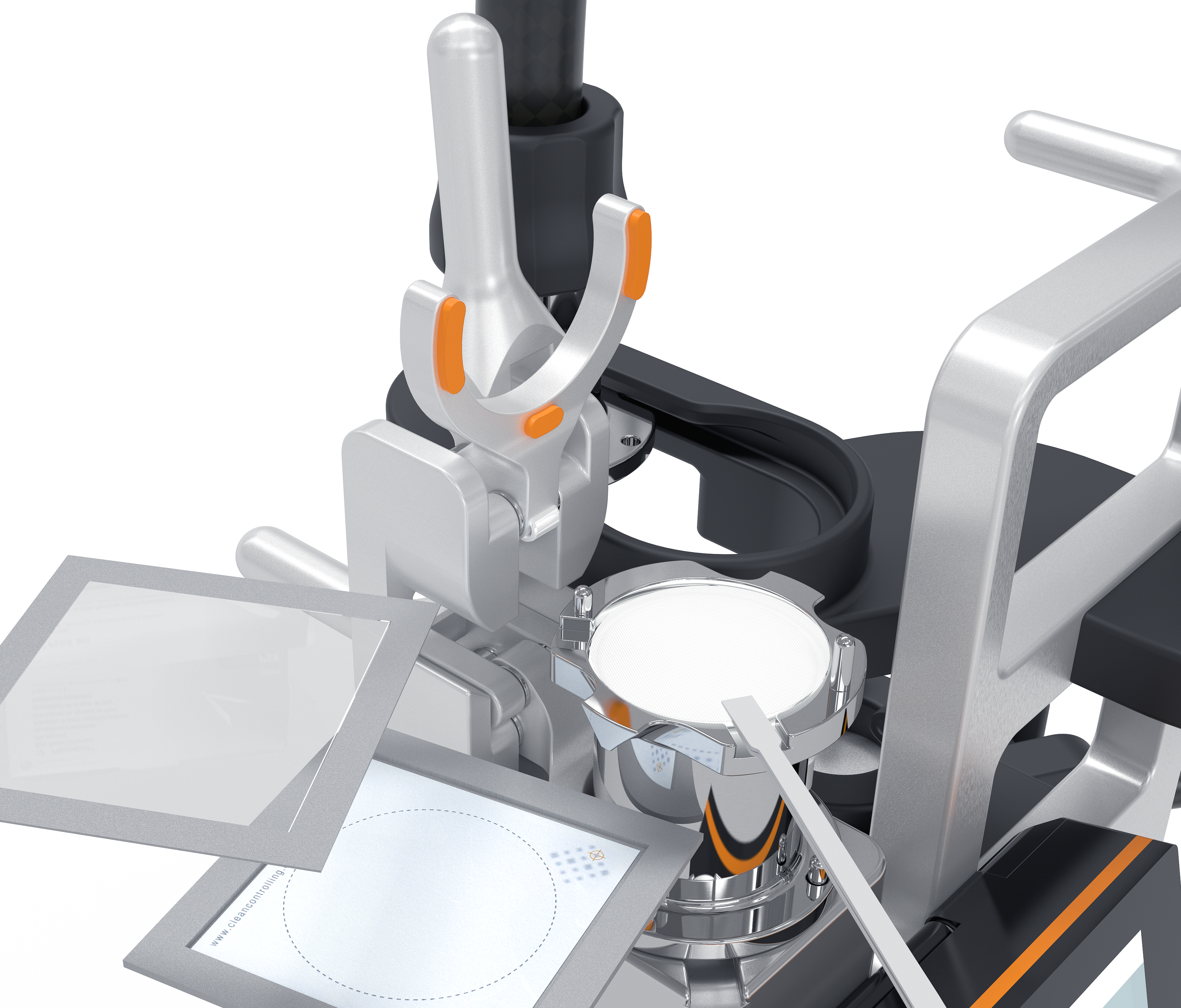

Several methods of particle separation are available for the suction extraction of the C|PS suction extraction system. This means that the system can cover a wide range of different applications.

Particle separation in the laboratory bottle

The extracted particles are collected in a clean laboratory bottle via the cyclone unit. For the subsequent analysis, the particles collected in the laboratory bottle are transferred to analysis filters by means of liquid analysis filtration and then analyzed optically and gravimetrically.

This method is particularly suitable for large component surfaces with a high particle load. It is characterized by the dry, non-destructive testing of large components, even with demarcated control areas.

Particle separation on the particle trap

The particles are separated from the suction flow in the cyclone unit and deposited on a particle trap mounted in the particle trap holder provided for this purpose. The particle trap can then be analyzed optically without further pre-treatment.

This method is suitable for components with smaller particle loads, i.e. components that tend to be smaller and "clean". It is characterized by the possibility of immediate light-optical analysis and the rapid availability of the results.

Direct filtration

The particles are extracted directly via the filter unit and separated from the air flow on the special analysis filter (>5µm). The analysis filter can be analyzed using optical light immediately after the suction extraction. If necessary, the filter coating can be prepared for light-optical analysis beforehand using the precoating unit. In addition, the precoating unit also enables a filter cascade in the event of higher particle volumes.

This method is suitable for testing small areas with a low particle load, e.g. in the process environment on workpiece carriers or for testing printed circuit boards. The filter coating can be prepared with liquid medium for analysis and then sucked dry. It is characterized by the rapid availability of the analysis filters for subsequent light-optical analysis.

Newsletter registration