Challenge of E-mobility: Cleanliness requirements of high-voltage vehicle batteries

require rethinking and incorporation of new extraction methods

In 2019 and 2020 CleanControlling supported several German OEMs and TIER1 in the development and industrialisation of high voltage vehicle batteries.

Due to the variety of potential damage mechanisms caused by particulate impurities, but also the dimensions of the components, a rethink is necessary with regard to the specification of cleanliness specifications, the integrated consideration of technical cleanliness in assembly, as well as the application of new extraction processes.

All OEMs are currently facing the challenge of bringing high-voltage vehicle batteries to series maturity in a very short time. Especially due to the fact that battery technology is new territory for many companies and not yet an "everyday business", many internal questions regarding the specification and analysis of particulate impurities remain unanswered. CleanControlling therefore supports several OEMs and TIER1 in the development and industrialisation of HV vehicle batteries in order to achieve a stringent and target-oriented concept of specification and analysis of technical cleanliness.

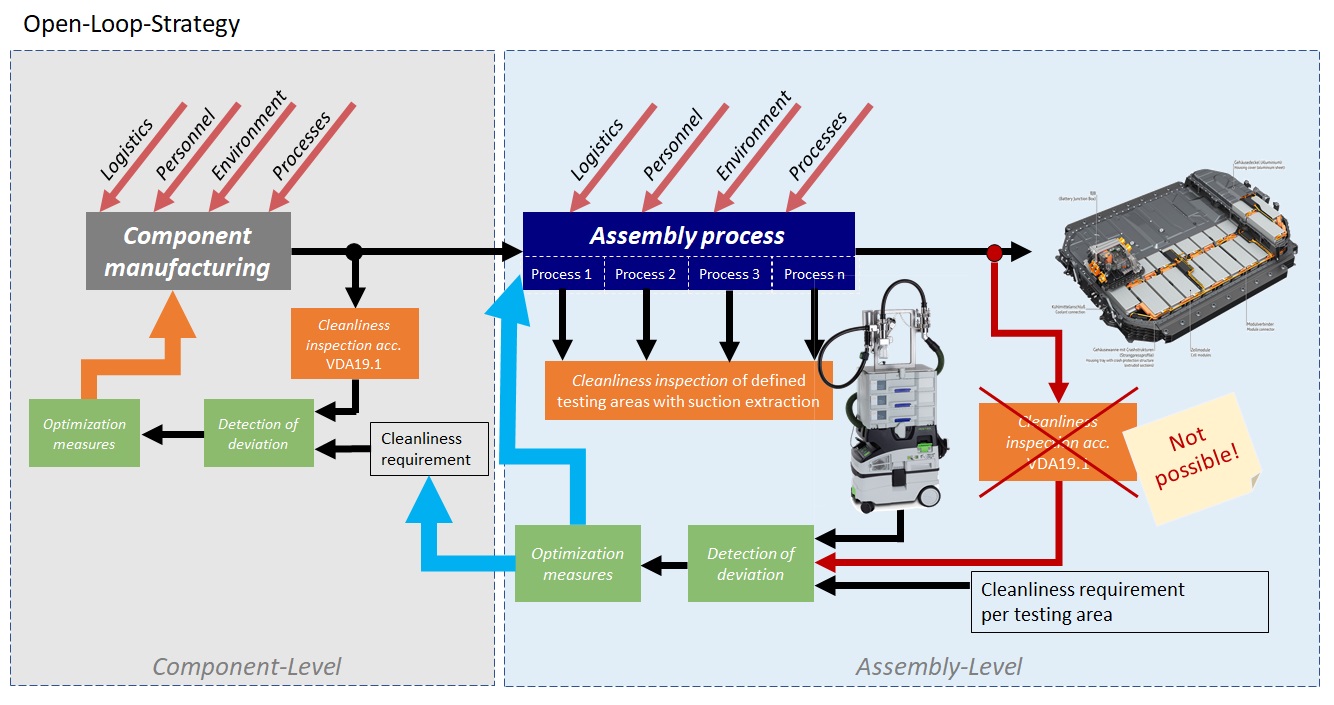

Open loop and reference area check instead of holistic cleanliness analysis

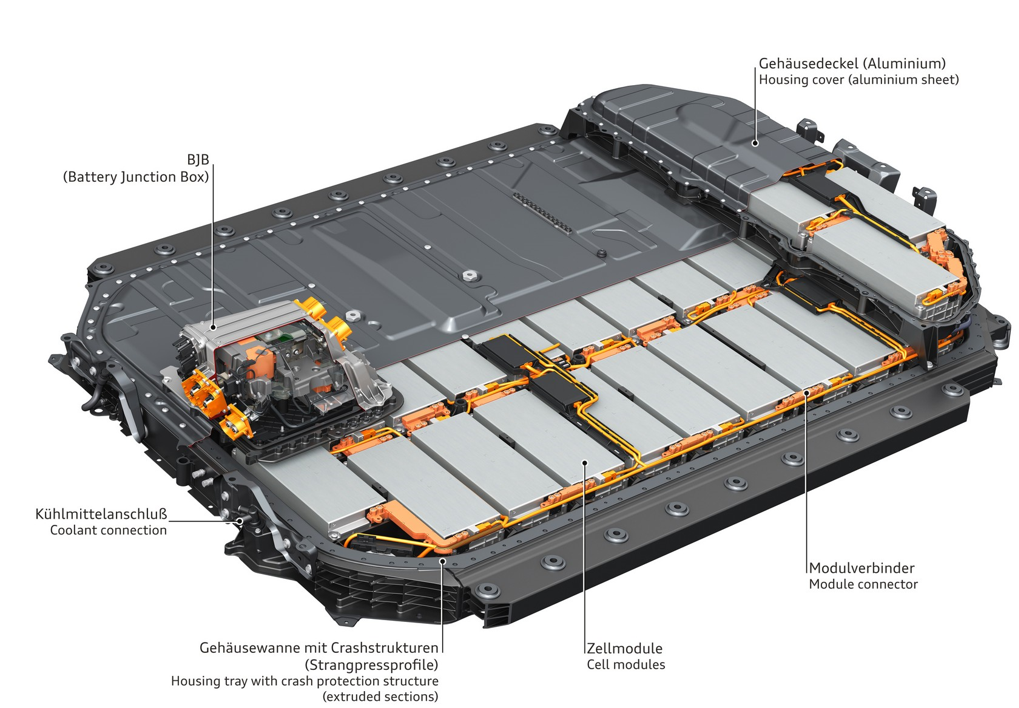

Current vehicle batteries are complex, mechatronic systems consisting of different assemblies. Some relevant properties such as...

- ... the component size of up to 2 metres,

- ... the accessibility to the areas critical to cleanliness,

- ... the use of electrical and electronic components,

- ... components which would be destroyed by contact with liquid,

- ... and last but not least high voltages and energy densities

put the extraction methods known and established from VDA19 to a critical test. The sum of these characteristics makes a holistic analysis of all surfaces according to the established methods of VDA19.1 almost impossible, which means that the cleanliness state cannot simply be achieved after the complete assembly in an extraction cabinet according to the methods of VDA19.1. The component dimensions alone and the high voltages and energy densities make this impossible. This makes it necessary to replace the "closed-loop" control cycle with an "open-loop" strategy. (see figure 1)

The "open-loop strategy" brings the cleanliness requirements of the critical component areas in line with the analysability of the areas. For this purpose, the critical component areas were identified and evaluated in several workshops on the basis of the damage mechanisms and subsequently individual limit values for particulate contamination were defined and validated. Each of these test points was selected and defined in such a way that they can be sampled directly in production during the corresponding assembly step and the tested battery can be further installed and delivered.

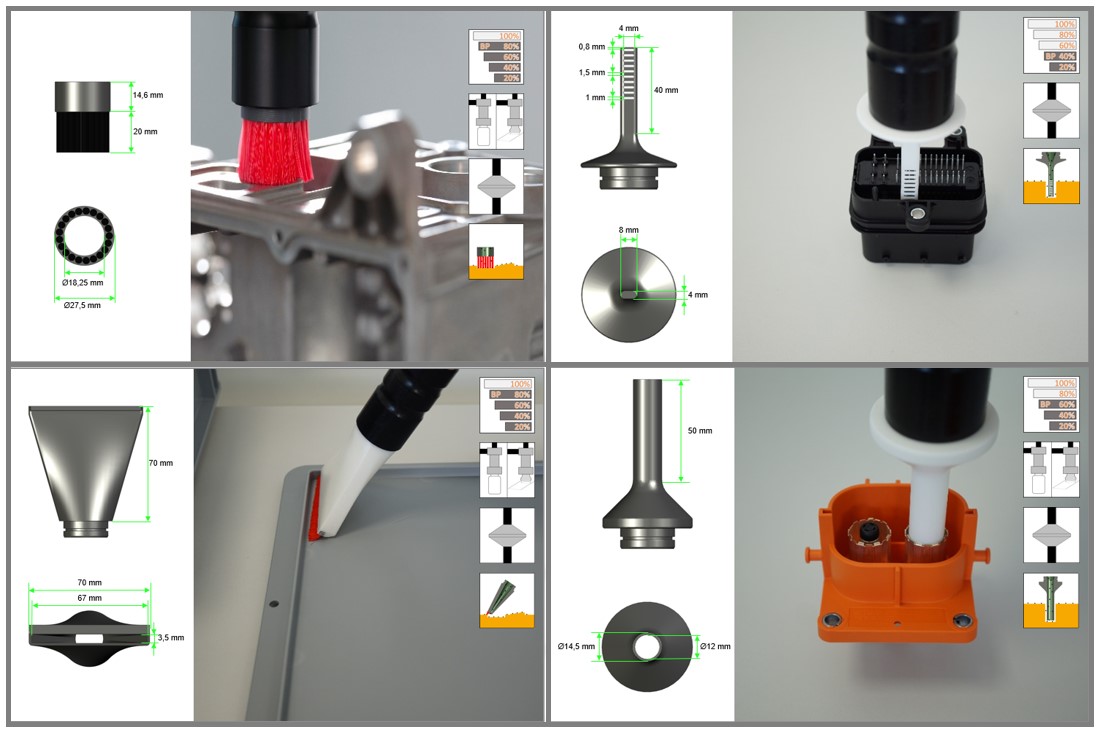

Extraction methods to assess cleanliness within the battery system

In order to be able to carry out the analysis of the corresponding test areas in a non-destructive manner directly in the assembly area, the suction extraction method could be found and defined. This method allows to extract limited component areas dry and non-destructively by guiding a nozzle adapted to the component along the relevant component surface and to dissolve the particulate contamination by a suitable combination of mechanical and aerodynamic cleaning factors. (see figure 3) In the assembly sequence, the partially assembled batteries can be stopped at defined intervals and the corresponding test areas can be extracted using the C|PS² suction extraction system. (see figure 2) The battery can then be reintroduced into the series assembly process and further processed. In the suction extraction system, the dissolved contamination is specifically deposited on a filter or in a laboratory bottle and can subsequently be analysed and evaluated using the analysis methods known from VDA19.1.

The "open-loop" strategy makes it possible to obtain cleanliness values of the battery system at the neuralgic points directly in the assembly process, to detect deviations and to define short-term optimisation or shutdown measures. A step towards more process safety, process knowledge and functional reliability in the manufacturing process and operation of vehicle batteries!

Support through fully integrated consulting approach

Especially the speed at which the development and industrialisation of batteries takes place requires an integrated consulting approach, which makes it possible to be part of the development process and to create and discuss necessary information, documents, specifications and design guidelines directly at the "point of use". This reduces communication across multiple interfaces and creates the necessary understanding and sensitivity for the topic of technical cleanliness among all stakeholders.

Previous report on this topic:

Further reports to this topic:

Newsletter registration