C|PS - Application examples

Robot guided suction extraction

Cleanliness tests on components that impose new requirements for particle extraction can be performed over the entire surface or part of it using the advantages of suction extraction in conjunction with a robot-based extraction system. These tests are especially beneficial in the field of electric vehicles, where they are conducted on items such as battery systems.

The robot-based solution developed specifically for this task provides automated and, consequently, reproducible sampling on components measuring up to 4,600 x 2,600 mm. The robot system’s seven degrees of freedom also allows particles to be extracted automatically from three-dimensional areas, such as recesses, holes or undercuts.

No special knowledge is required to program the robot; the extraction motion sequence is simply created by a one-time manual teach-in session and can be saved as a component-specific program.

Shortened direct analysis in connection with surface measuring system

Schnell ermittelte Sauberkeitswerte.

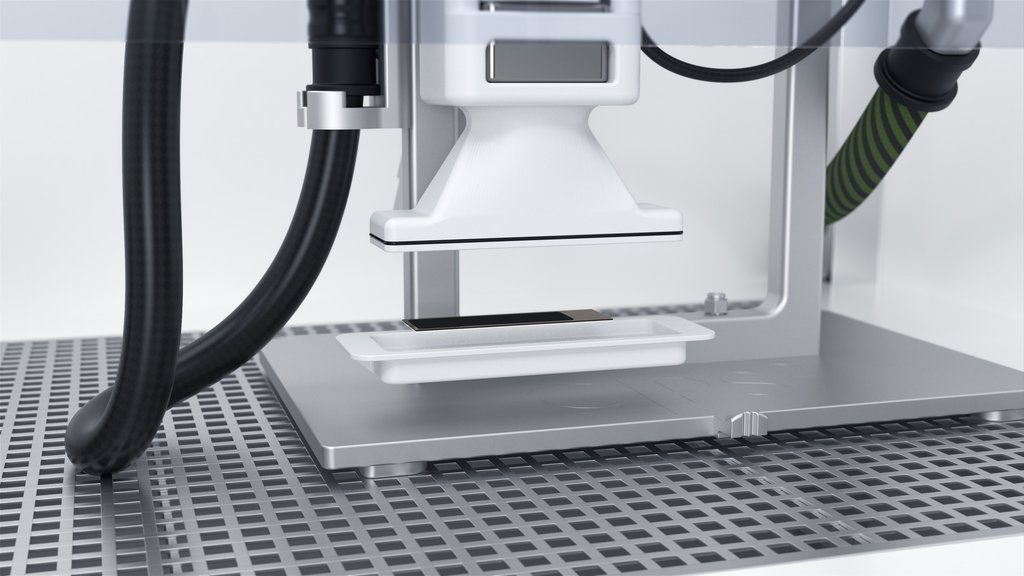

Shortened direct analysis in conjunction with PartSens 4.0 surface measurement system

Schnell ermittelte Sauberkeitswerte.

A reduced direct analysis can be performed in combination with a surface measurement systemPartSens 4.0 by PMT Partikel Messtechnik GmbH. The special analysis pads for direct analysis with the PartSens 4.0 are attached to the cyclone unit using the special analysis pad holder. Optimal testing of highly sensitive components is performed within a laminar flow environment, made possible by the extraction system’s mobile design. Suction extraction in the laminar flow environment extracts particle contaminants from the component with the lowest possible blank value. The extracted particles are deposited onto the adhesive analysis pad.

The analysis pad is then inserted into the PartSens measuring head of the PartSens 4.0. The series measurement process commences and is performed five times. The results of the five series measurements are combined and displayed as an overall result. The measurement result is very close to the light microscopic analysis according to VDA 19.1. In addition to the measurement of the particle length as Feretmax, the PartSens+ 4.0 offers the option of distinguishing between particle sizes and particle numbers of metallic and non-metallic particles as well as fibers.

Newsletter registration