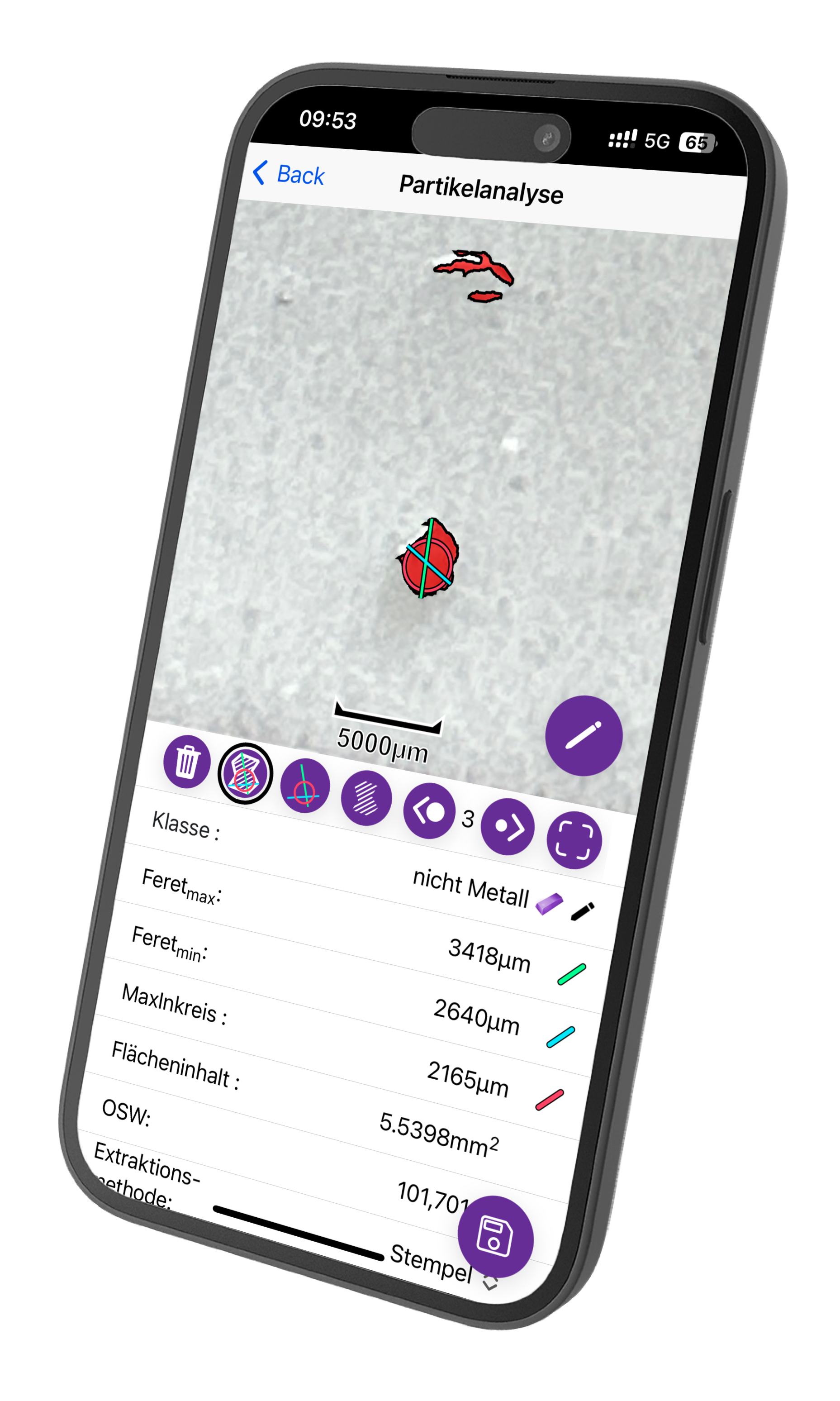

Fast direct analysis with Clever-Stamp and ParticleLens app

Quickly determined cleanliness values.

Direct analysis with the ParticleLens app of PartikelART is suitable for quick and regular checks, for example as part of monitoring in the process environment.

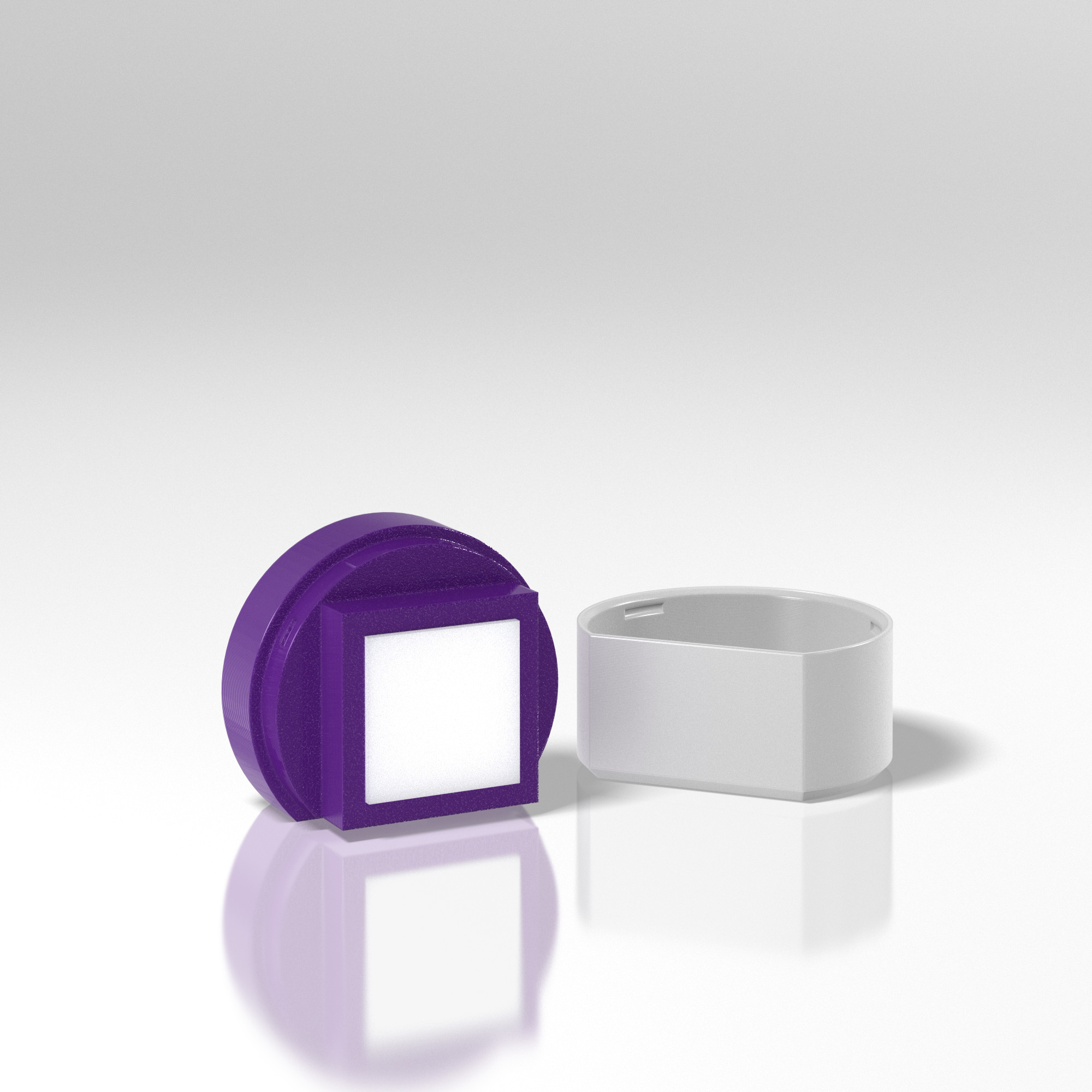

For this purpose, the Clever-Stamp is attached to the special, optionally available adaptation as a particle trap. After suction extraction, the Clever-Stamp can be analyzed digitally quickly and cost-effectively using the PartikelLens app.

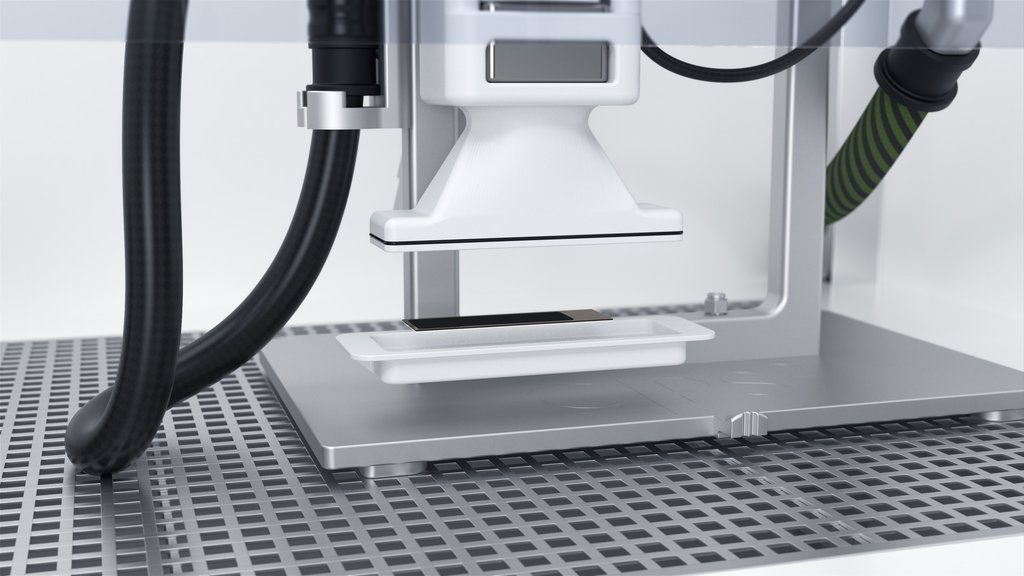

Shortened direct analysis in conjunction with the PartSens 4.0 surface measurement system

Schnell ermittelte Sauberkeitswerte.

In combination with the PartSens 4.0 surface measurement system from PMT Partikel Messtechnik GmbH, a shortened direct analysis is possible. Testing is ideally carried out within a laminar flow environment in order to keep the blank value as low as possible. This is made possible by the mobile design of the extraction system.

The special analysis pads for direct analysis with the PartSens 4.0 are attached to the cyclone unit using the specific, optionally available adaptation. The extracted particles are deposited onto the adhesive analysis pad. A 5-fold serial measurement is then carried out with the PartSens measuring head of the PartSens 4.0. The five serial measurements are summarized as an overall result. The measurement result comes very close to the light microscopic analysis according to VDA 19.1.

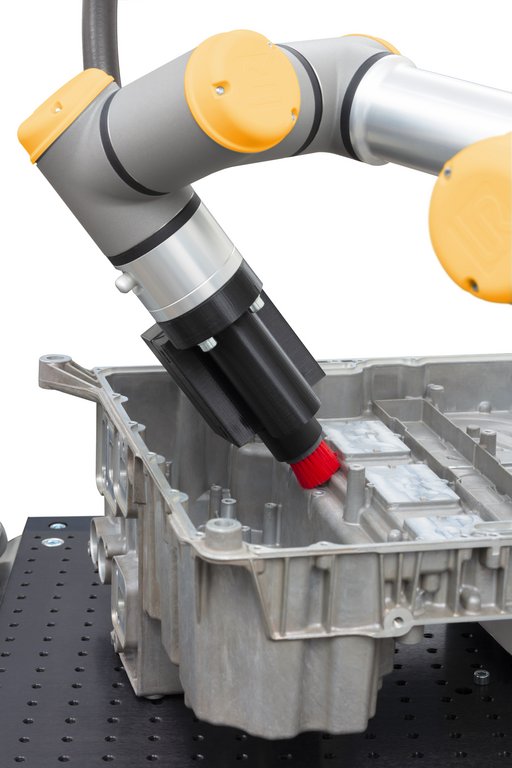

Robotergeführte Saugextraktion

Cleanliness inspections of large components, for example for battery systems, place new demands on particle extraction. This is often required during the production process. Robot-guided suction extraction enables automated and reproducible sampling, either over the entire surface or at different control points.

For such applications, CleanControlling uses a robot-based solution developed in-house for components measuring up to 4,600 x 2,600 mm. Thanks to the robot system's seven degrees of freedom, particles can also be automatically extracted from three-dimensional areas including recesses, holes or undercuts.

The robot's movement sequence for extraction is programmed by simple manual teaching and saved as a component-specific extraction program.

Newsletter registration