Design and manufacturing of test adaptations

In many cases, component cleanliness is only relevant for areas exposed to media and is therefore only regulated for these so-called control areas. Therefore, it is important to exclude the non-relevant areas from the cleanliness inspection, which may also have a negative influence on the result because these non-relevant areas do not have the same high level of cleanliness in the manufacturing process as the relevant areas.

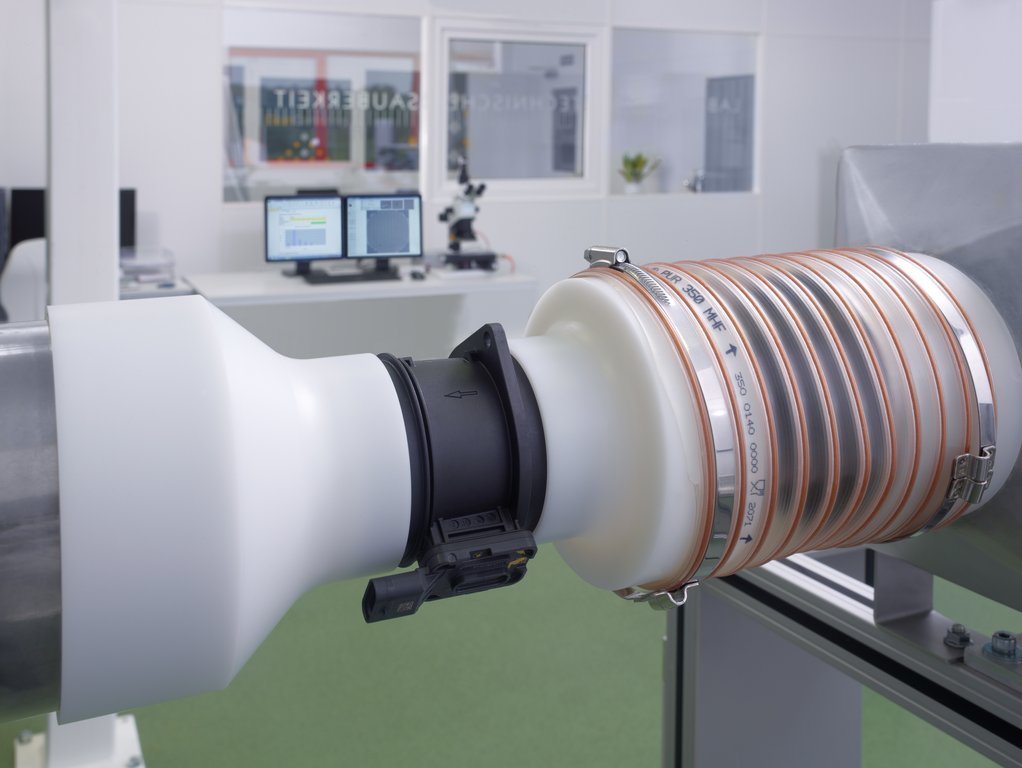

The reliable separation of the non-relevant areas can only be achieved in an optimal way with suitable component-specific adaptations or testing fixtures. Even active components that have to be opened or switched for testing require special component-specific testing fixtures. These adaptations and testing fixtures thus ensure test results with high reproducibility for the following applications:

- Extraction and flushing of pipes, ducts, filters, heat exchangers, valves, injectors, etc.

- Extraction of components with complex media areas, e.g. cylinder heads, crankcases, etc.

- Holding and masking of smallest components for targeted pressure-rinsing extraction

- Connection to flow-through test stand for air through-flow extraction

CleanControlling has the special knowledge and experience for the design of component-specific, flow-optimized adaptations and active testing fixtures. Based on the CAD data of the component, CleanControlling designs the optimal adaptation and manufactures it preferably from white POM plastic with a cleanness suitable surface finish. CleanControlling archives the adaptations with reference to the respective test specification and thus ensures short term repeat tests.

Profile

| Typical industries | Automotive and automotive supply industry, precision engineering, etc. |

|---|---|

| Type of contamination | particles from manufacturing process |

| Test objects | media exposed component areas |

Further Information

If you have any questions, the employees from our sales team will be happy to help you.

Newsletter registration