Practical example 2

Damage finding: white residue on metal component

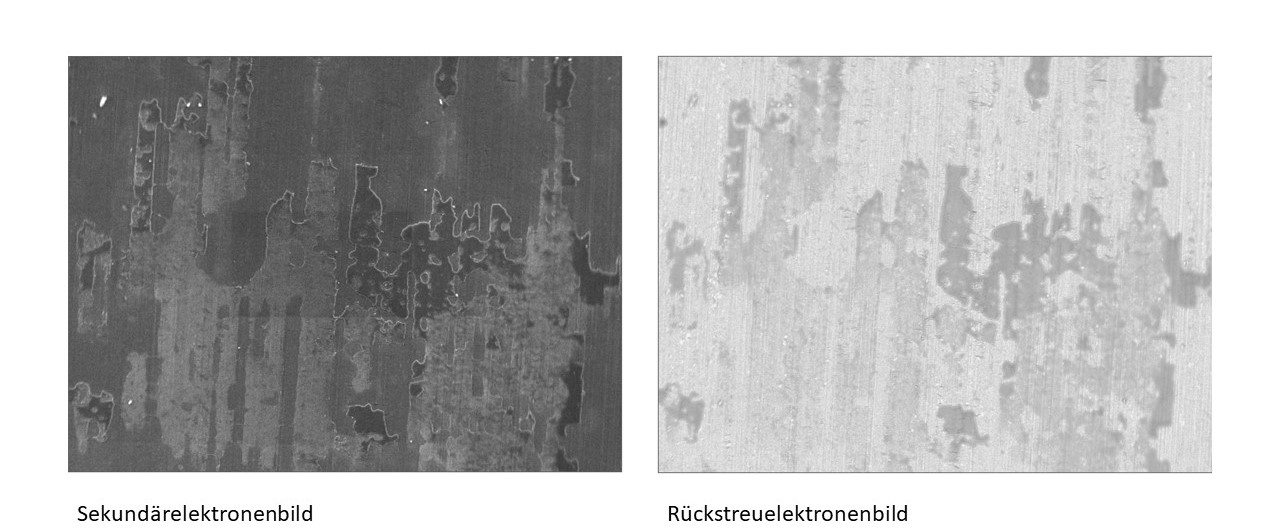

1. SEM image evaluation

The secondary electron image of the sample shows an overlying contamination with sharp edges. The backscattered electron image clearly shows that the impurity has a density similar to that of the component. The image evaluation of the SEM images suggests an inorganic contamination. Organic compounds would appear softer and darker.

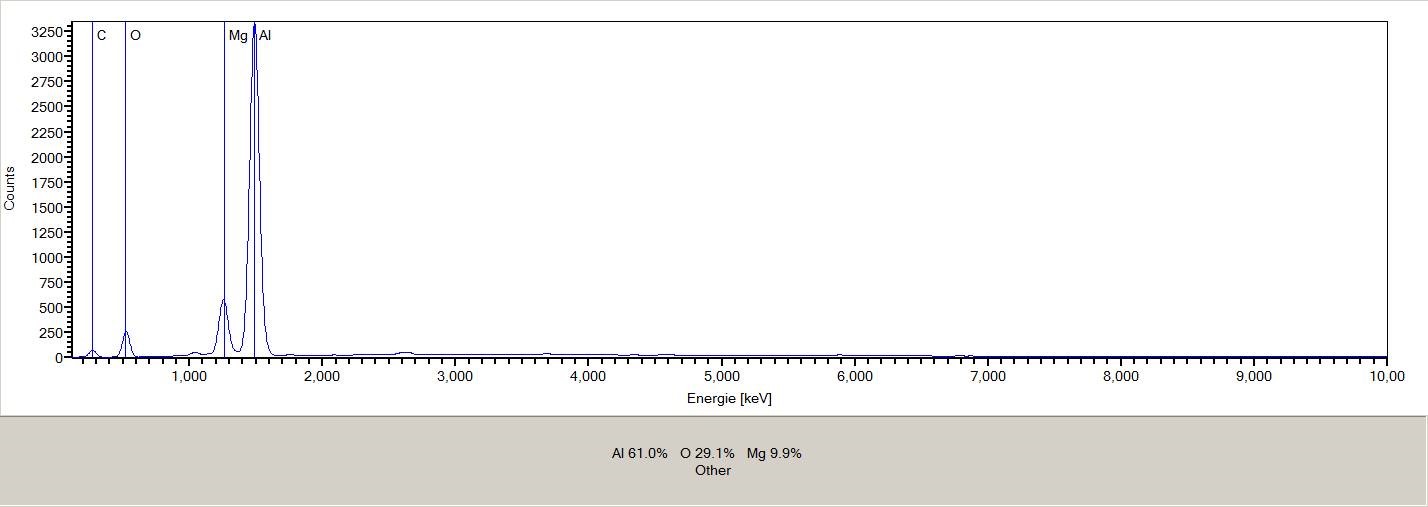

2. EDX Spectral evaluation

The EDX spectrum primarily shows the elements aluminium and magnesium. This matches the AlMg3 material of the component. The carbon content is very low. Although this cannot be evaluated quantitatively, the impurity seems to be mainly inorganic. Furthermore an intensive oxygen peak is found. The low carbon content, the high oxygen value and the absence of other elements indicate an oxide material.

3. IR spectral evaluation

The infrared spectroscopy shows no IR-active (organic) residues on the component.

Conclusion:

It is aluminium oxide on the surface of the component. In discussions with the customer, it was found that a change from a fast volatile to a water-based cooling lubricant was made at the same time as the problem occurred. As the components were not dried after machining, the observed corrosion damage occurred.

Newsletter registration