Determination of the conductivity of residues

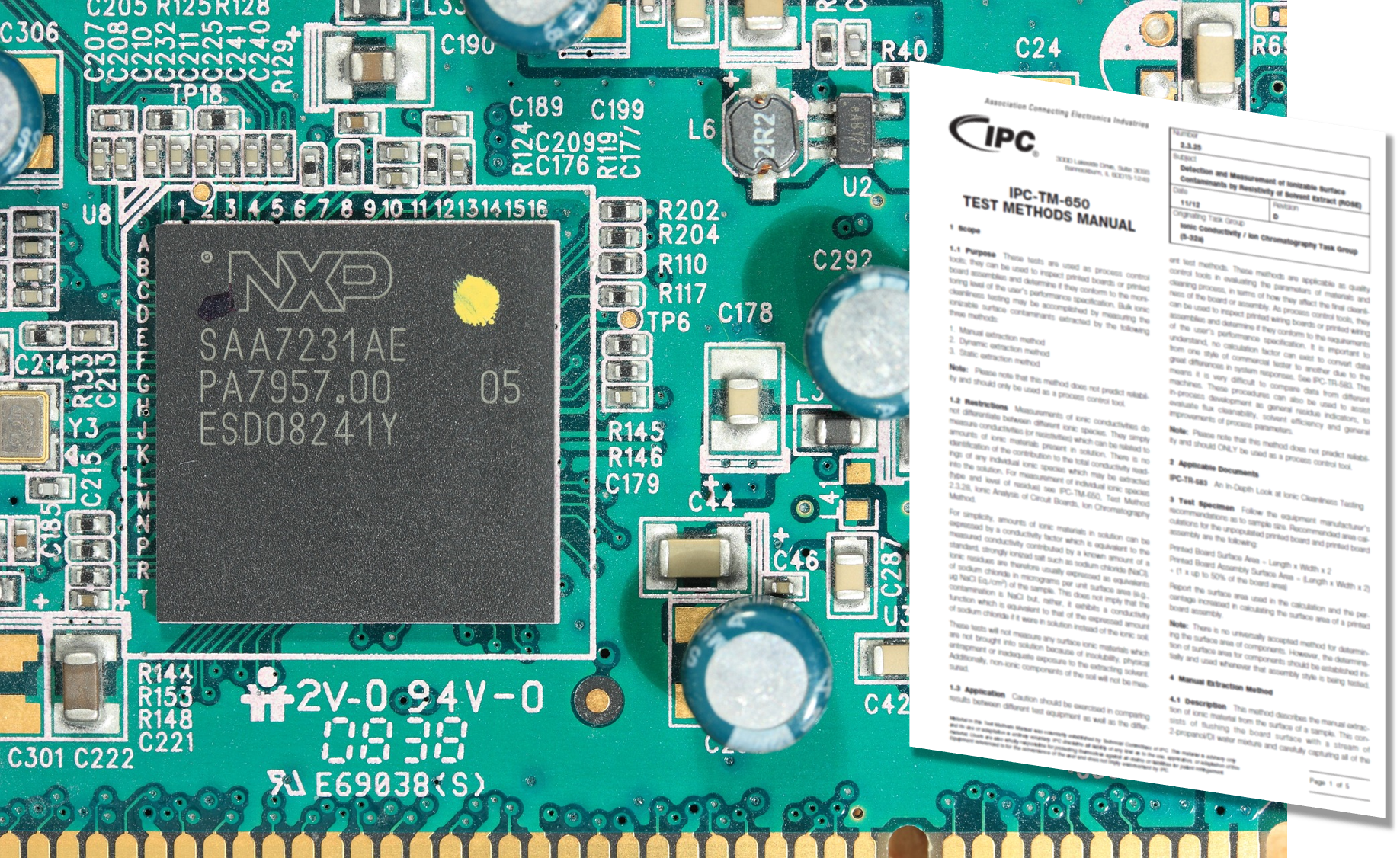

Resistivity Of Solvent Extract (ROSE) measurement

The ROSE (Resistivity Of Solvent Extract) measurement is a fast and cost-effective method to determine the conductivity of residues on electronic components. Fluxes, such as potassium fluoride, are an important component of solder pastes. However, if they remain on a printed circuit board, their hygroscopic properties can lead to corrosion and thus to malfunctions and failures. To ensure a sufficient quality of the soldered parts, it is thus not necessary to characterize all the ions present separately but to focus on the resistivity of the entire contamination. Therefore, the ionic residues are extracted, either by rinsing or by submersing the sample in a suitable solvent. Depending on the applied test specification, the resistivity of the resulting solution is determined during or after the extraction process. Subsequently, the results are calibrated versus sodium chloride and the results converted to µg NaCl equivalents per cm². The measurements carried out by CleanControlling are based on the common test specifications IPC-TM-650 2.3.25 and IPC-TM-650 2.3.25.1.

Profile

| Typical industrial branches | Electronics / circuit board production |

|---|---|

| Type of contamination | Ionic contamination from soldering processes |

| Result | µg NaCl equivalents / cm² |

| Testing standards and regulations | IPC-TM-650 2.3.25, IPC-TM-650 2.3.25.1 |

Further Information

These tests are part of our accreditation, detailed information on the scope of accreditation can be found here.

You can also find an overview of tests for chemical-film contamination in our current brochure.

If you have any questions, the employees from our sales team will be happy to help you.

Newsletter registration