(Brush) suction extraction according to VDA 19.1

The third edition of VDA 19.1 published in 2025 brings with it some significant innovations, particularly with regard to (brush) suction extraction. This method is becoming increasingly important, as it is often the only practicable alternative to liquid extraction for certain components such as battery systems, high-voltage or electronic parts. Volume flow measurement plays a central role here. It ensures that cleaning results are reproducible and comparable.

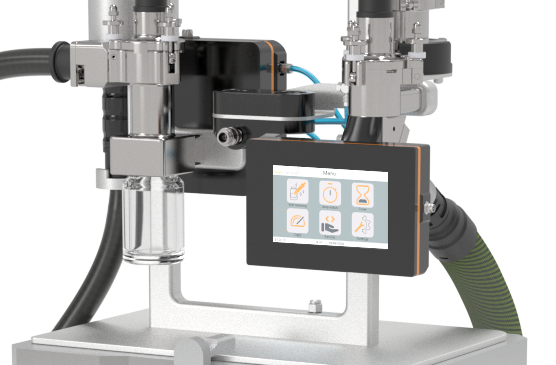

Volume flow measurement of the C|PS² suction extraction systems

The C|PS² suction extraction system developed by CleanControlling some time ago as an alternative extraction method for such applications has already been in use for several years. It has a measuring device for indirect measurement of the volume flow by means of differential pressure measurement in mbar. The factory-set volume flow is monitored indirectly via the recommended differential pressure.

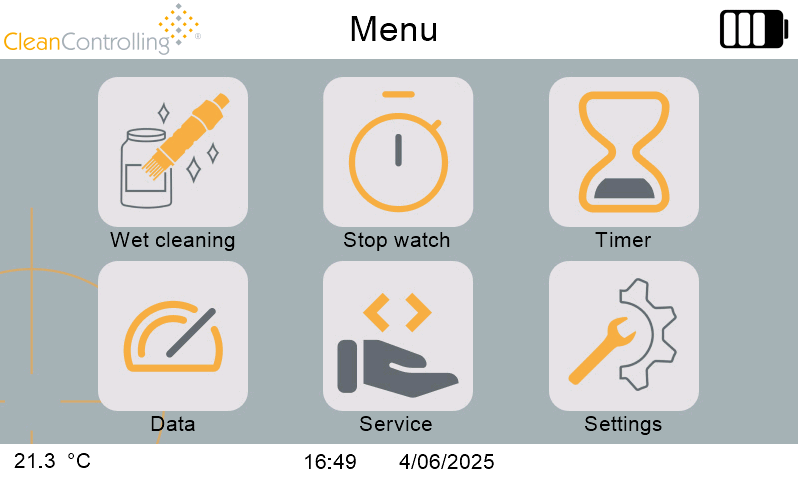

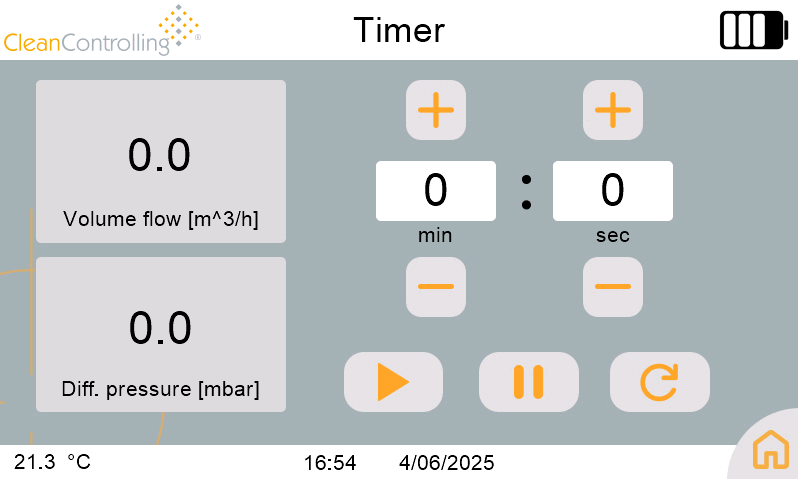

CleanControlling has developed a new measuring device with touch display and all functions relevant for suction extraction in order to be able to reliably monitor the new normative requirements and parameters of VDA 19.1.

Parameters conform to VDA 19.1

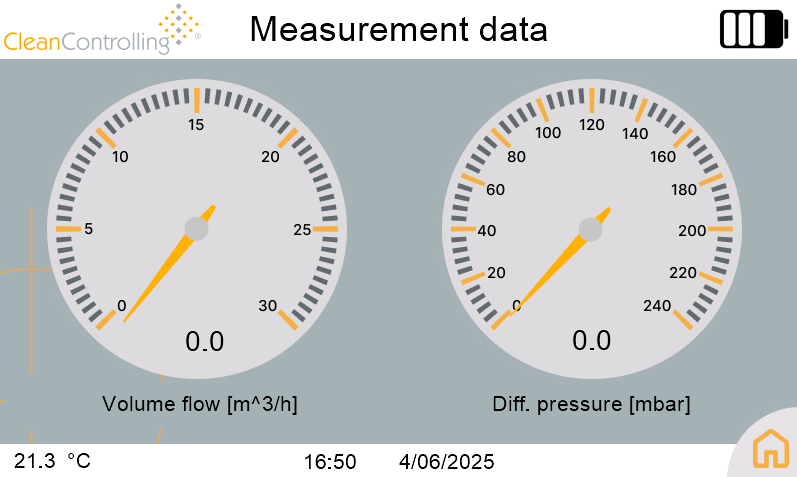

The new touch display is used to continuously display the volume flow and differential pressure in real time. Additional functions such as a timer and stopwatch as well as guided wet cleaning of the system are also integrated.

The volume flow of the particle suction extraction system is measured and calculated using the differential pressure measurement method below the analysis filter. Maintaining a constant volume flow is an essential parameter for the reproducibility of the selected test parameters. It can be reliably monitored via the volume flow display.

Functions

- Measurement and display of volume flow (m³/h) and differential pressure (mbar)

- Stopwatch

- Timer

- Guided wet cleaning

- Control function for emptying the vacuum cleaner and venting the measuring device

Retrofitting C|PS² suction extraction systems

When developing the system, particular attention was paid to backwards compatibility for C|PS² systems. This means that all C|PS² systems built from 07'2019 onwards can be retrofitted by the user. No factory assembly work is required. The retrofit can easily be carried out by the laboratory staff themselves.

Newsletter registration