Practical example 1

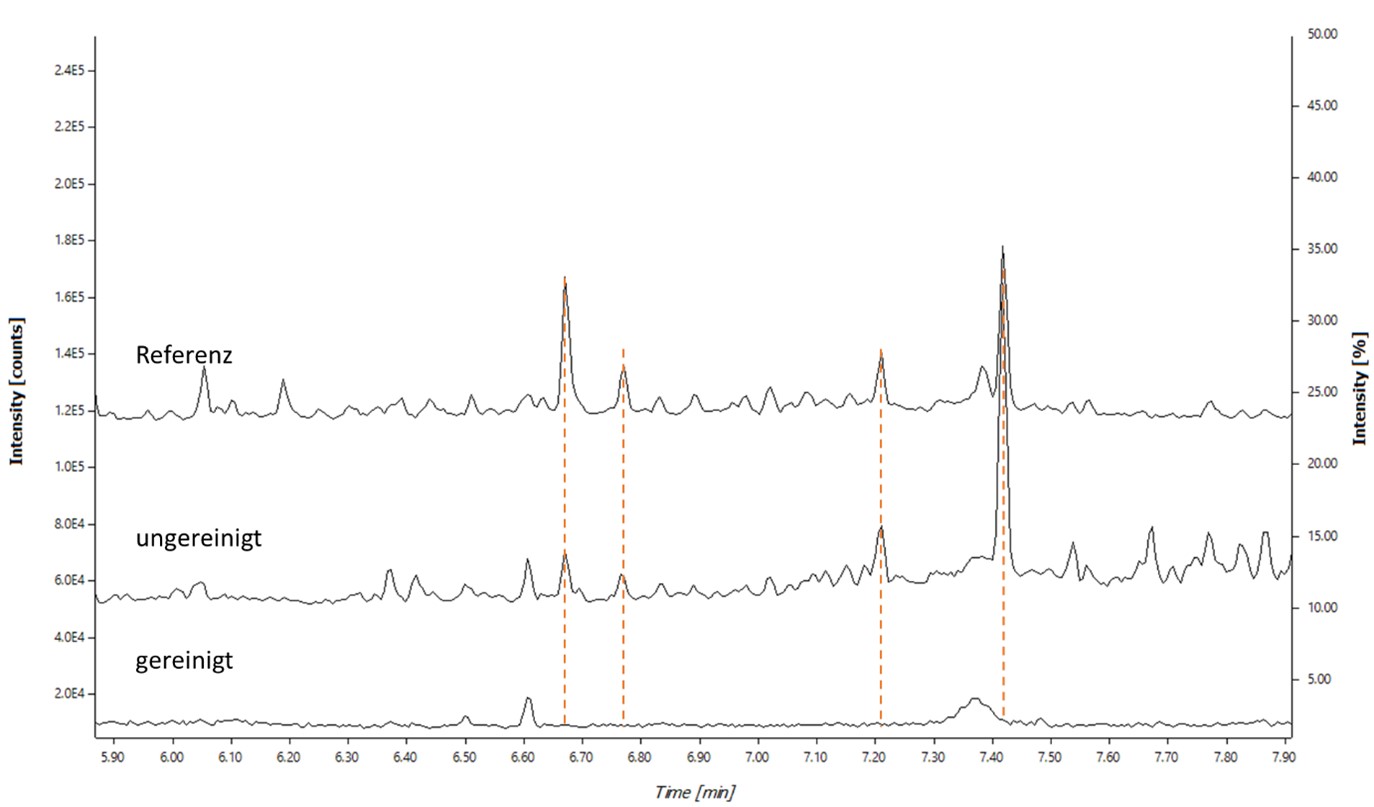

One component was treated with a lubricating oil for assembly and then cleaned.

For the analysis, a cleaned component, an uncleaned component and a sample of the used lubricant were provided as reference.

The comparison of the three chromatograms clearly shows that the contamination on the component corresponds to the oil used. It can also be seen that the cleaning process after assembly is successful but also necessary to obtain a clean component. First of all, it is irrelevant which composition the oil is made up of. Nevertheless, this information can be used to further optimize cleaning processes.

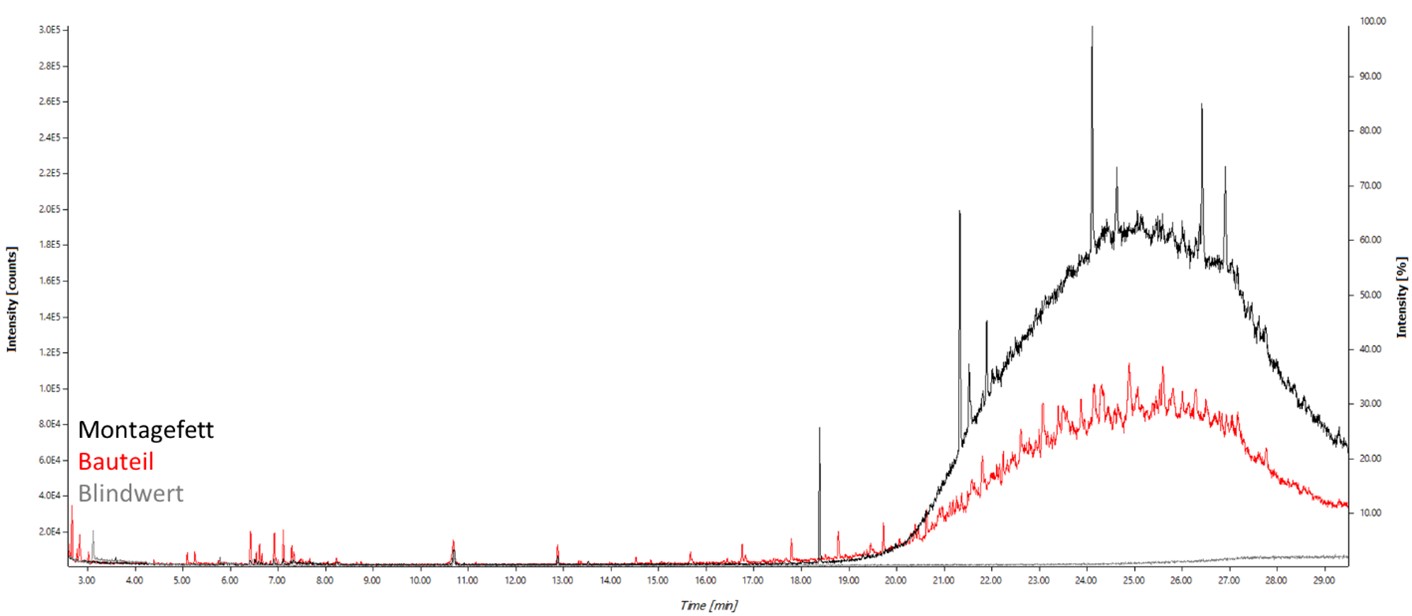

Practical example 2

In a cleanliness analysis according to VDA 19.1 the gravimetric limit value is exceeded. It is assumed that in addition to the relevant particles, undissolved residues of the used assembly grease have also been left on the filter. A comparison measurement between the assembly grease and the extracted residues on the analysis filter clearly shows that these are identical and therefore the assembly grease and not the particulate contamination is the n.o.k. result has caused.

Please contact our sales team, we will be happy to advise you on your specific requests.

Newsletter registration