Analysis methods for additive manufactured products

Testing of material characteristics and end products

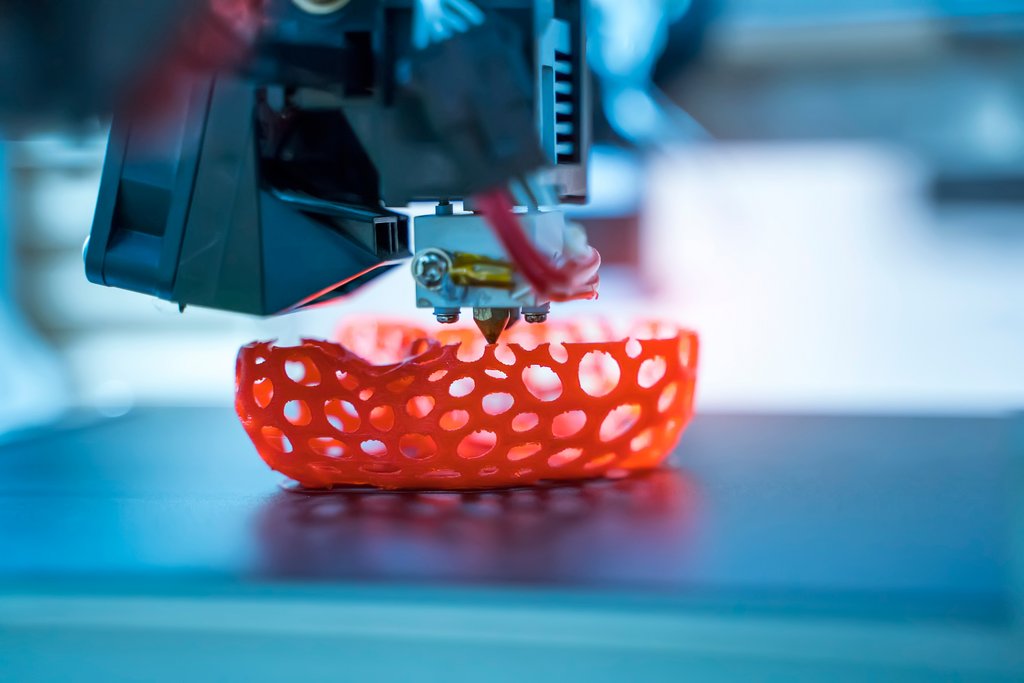

Additive Manufacturing (AM) in Medical Technology

Additive manufacturing technologies are increasingly finding their way into the individual and series production of medical devices. Here, very individual and application-specific products can be created. This offers many possibilities, but also brings previously unknown challenges that go far beyond the issues of conventionally manufactured products.

With intensive research work, the IWAT Institute of the HFU Furtwangen has identified emerging risks of additive manufactured medical devices and established suitable test methods. Based on these scientific findings, CleanControlling Medical offers customized analysis procedures to specifically identify these risks and ensure the quality of the manufactured products.

Quality of the manufacturing process

Chemical composition

- X-ray fluorescence analysis (XRF) *

- Energy dispersive X-ray spectroscopy (EDX)

- Optical Emission Spectroscopy (OES) *

Volume state

- Powder material quality (chemical composition / particle properties) *

- Computed Tomography (CT) *

- Metallography *

Surface condition

- Powder material quality (chemical composition / particle properties) *

- Light microscopy (LM)

- Scanning Electron Microscopy (SEM)

Biocompatibility

- Product quality (Chemical characterization / Cytotoxicity)

- GC-MS, ICP-MS, LC-MS, HS-MS, TOC

- toxicological evaluation according to DIN EN ISO 10993-17

- cytotoxicity test according to DIN EN ISO 10993-5

Quality of powder material

Chemical composition of the powder material

- X-ray fluorescence analysis (XRF) *

- Energy dispersive X-ray spectroscopy (EDX)

Topography / morphology of the powder material

- Light microscopy (LM)

- Scanning electron microscopy (SEM)

Mechanical and chemical characteristics

Static mechanical characteristics

- Universal testing equipment (tensile / compression test) *

- Hardness test according to Vickers or Rockwell *

Dynamic mechanical properties

- Fatigue test *

Toxicity

- Electrochemical analysis *

* These tests do not fall within the scope of accreditation and also not of recognition on the part of ZLG and GLP.

Newsletter registration