In vitro cytotoxicity test of medical devices

Cytotoxicity is understood as the ability of a substance to damage tissue or cells. Cytotoxicity testing according to DIN EN ISO 10993-5 is one of the most important test methods in the context of the biological assessment of medical devices. The aim of a cytotoxicity test is to assess the safety of the medical device that is used on (e.g. prosthesis) or in humans (e.g. implant). In this context, the in vitro cytotoxicity test is of particular importance, as the test detects any type of cytotoxic effect of a product. However, the test only detects possible cytotoxicity without specifying the exact cause.

How is cytotoxicity testing performed?

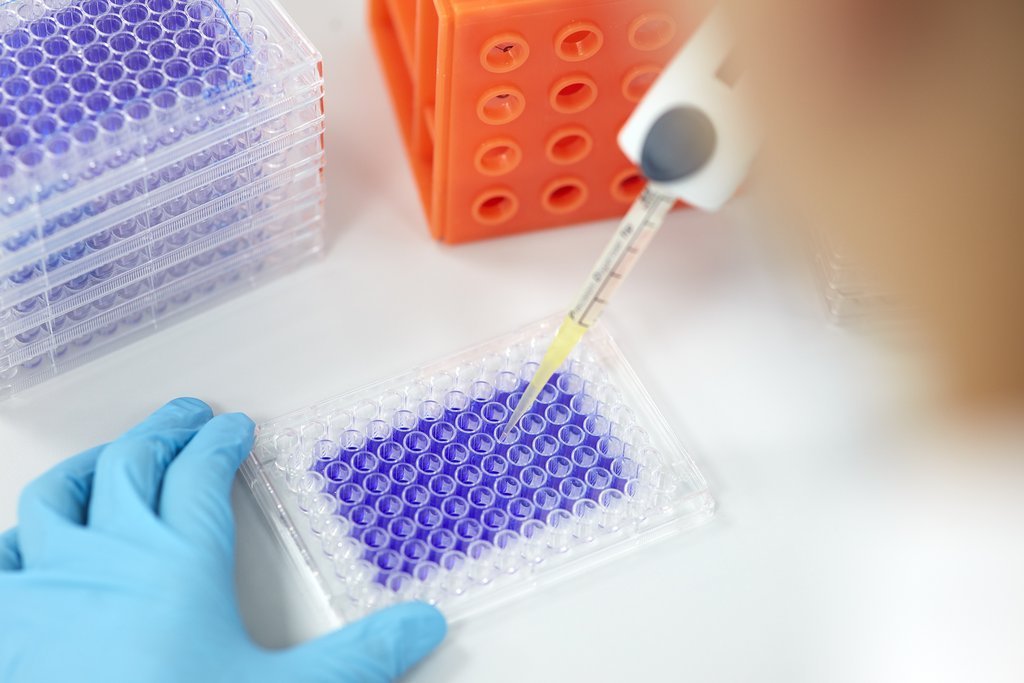

For the in vitro cytotoxicity test, connective tissue cells are used, so-called fibroblasts, because these cells have a high sensitivity to toxic substances. The cells are incubated either with the product itself or an extract from the product for 48 to 72 hours. At the end of the incubation, the cells are examined under the microscope for morphological changes as well as for altered growth behavior. Subsequently, the cells are stained to quantify the exact cell number.

The ratio of the number of cells that have come into contact with the product to control cells that have not come into contact with the product can be used to determine the influence of the product on the growth (proliferation) of the cells and to make statements about whether the product inhibits the growth of the cells.

A toxic effect can be caused by the product itself, i.e. by material and coating, by residues on the surface, e.g. from cleaning agents or disinfectants, or by contamination on the surface of the product. Therefore, a positive result of an in vitro cytotoxicity test may lead to a series of further tests to narrow down and determine the exact cause of the cytotoxicity of the medical device.

Determination of cytotoxicity according to DIN EN ISO 10993

The Medical Devices Act obliges manufacturers of medical devices to subject them to comprehensive testing to protect patients before placing them on the market. Our accredited testing laboratory carries out tests on the cytotoxicity of medical devices in accordance with the specifications of DIN EN ISO 10993 - "Biological evaluation of medical devices".

This standard, which is primarily relevant for manufacturers of medical devices as well as for testing laboratories, pursues the goal of evaluating the biological compatibility of medical devices. The normative requirements apply not only to finished medical devices, but also to the individual starting materials from which they are manufactured.

DIN EN ISO 10993-5 defines limit values for assessing the cytotoxicity of materials and products. Two criteria are mentioned that can be used to determine whether a substance is to be classified as cytotoxic:

- "A reduction of cell viability by more than 30% is considered a cytotoxic effect."

- "Achieving a numerical degree classification of more than 2 according to Tables 1 and 2 is considered a cytotoxic effect."

(Source: DIN EN ISO 10993-5, Section 8.5)

However, a cytotoxicity test alone is not sufficient as proof of the biocompatibility or purity of a medical device. This is because a passed test is not in itself a guarantee that the medical device does not contain critical residues or that the material releases problematic substances. This is because even if many different substances show up well even in low concentrations: If the concentration is too low, the in vitro cytotoxicity test is nevertheless limited in its informative value and does not signal a cytotoxic effect, although the substances in question may in fact be toxicologically very relevant. For this reason, further analytical methods should always be selected in order to be able to completely exclude the risk of cytotoxicity of medical devices.

Cytotoxicity testing by our accredited, ZLG and GLP approved laboratory.

CleanControlling Medical GmbH & Co. KG, as a ZLG-approved testing laboratory, offers a wide range of tests to determine the chemical, biological and particulate cleanliness status of medical devices. We are a testing laboratory for cleanliness testing of medical devices accredited according to DIN EN ISO 17025:2018 by the German Accreditation Service and recognized according to GLP.

The accreditation confirms that our testing laboratory meets all internationally applicable quality and competence requirements. This ensures that the results determined by our testing laboratory are internationally comparable and can also be recognized during an audit.

Thanks to the GLP recognition of our testing laboratory, mutual recognition of tests by the regulatory authorities of the member states of the OECD (including Europe, USA, Canada, Japan, Mexico and Australia) is possible, provided that these tests have been performed in accordance with GLP principles. Therefore, our test results are also recognized by the FDA, for example. We prepare our test reports FDA-compliant and always in bilingual versions (German/English) for international use.

As an accredited testing laboratory for medical devices, we rely exclusively on well-qualified and competent testing personnel. All our laboratory staff have an appropriate academic education (doctorate, bachelor/master biology, biotechnology) or are trained biological-technical assistants. This enables us to offer you a comprehensive range of services - including personal support in the interpretation of test results, if required, on site in your production or packaging areas.

Do you have any questions about cytotoxicity, our range of tests or our other services and products? We are happy to help you on the phone and can be reached daily from Monday to Friday continuously from 07:30-16:30 at +49 7465/92 96 78-0. Alternatively, you can also use our contact form to send us your request in writing.

Procedure of the test

| Extraction | Extraction of the product in a cell culture medium for 24h |

|---|---|

| Incubation | Incubation of the resulting extract with fibroblasts (connective tissue cells) for 48-72h |

| Measurement | Testing for growth inhibitory properties of the product by microscopic assessment and staining of the cell unit |

| Unit | % Growth inhibition |

Newsletter registration