Fibers - Design of the production environment

The production of functional automotive components requires defined and monitored component and assembly cleanliness to ensure product quality and reliability. One of the challenges in this area that is becoming increasingly important is fibers, which are omnipresent in manufacturing environments. This white paper highlights the most important aspects of designing the manufacturing environment to avoid or at least reduce contamination with fibers in a controlled manner.

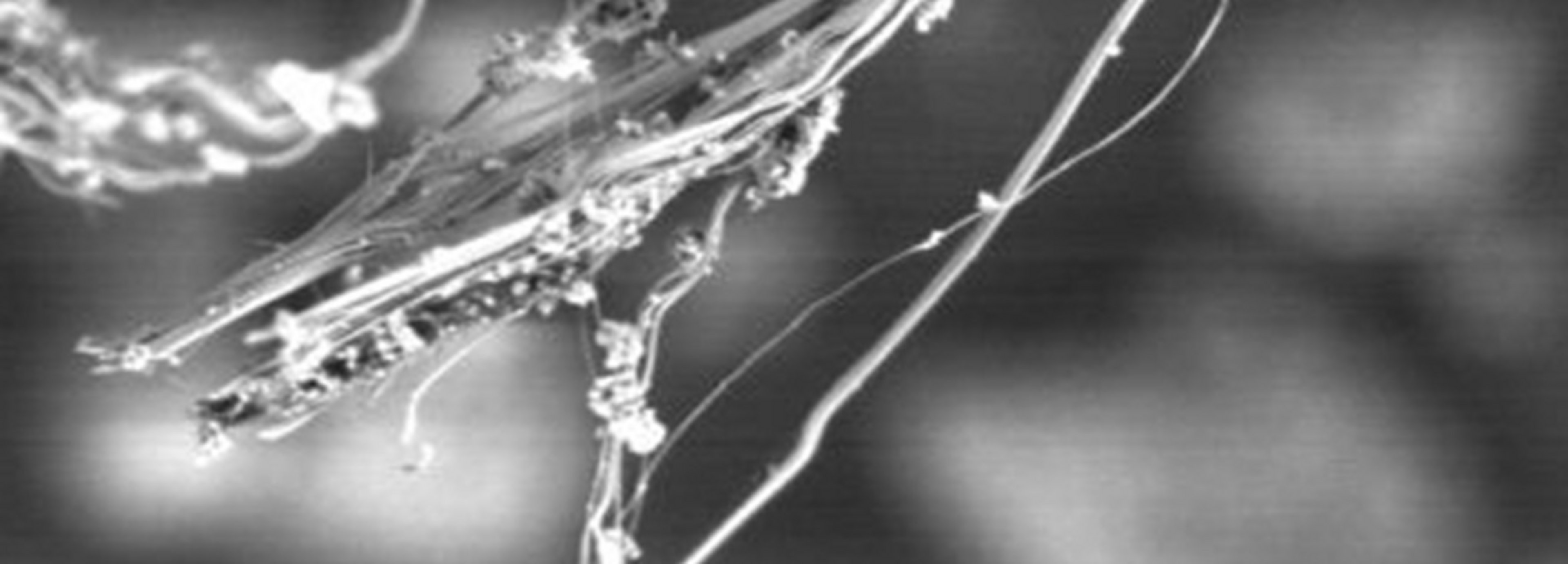

Fibers in technical cleanliness

Contamination with fibers can come from various sources, for example from production processes, materials or the environment itself. Textile fibers in particular are almost ubiquitous, even under cleanroom conditions. While the individual fiber is often not functionally critical, a high concentration of fibers can be functionally critical. Fiber contamination of this kind can lead to malfunctions, quality defects and increased failure rates. A targeted contamination control concept is therefore recommended.

Critical points in the regulation of fibers

Until now, it was generally assumed that fibers and lint are irrelevant, which is why they were only considered marginally. Three reasons are given for this.

Measurement technology

Depending on the amount of fibers, fiber conglomerates can form on the analysis filter during extraction and analysis filtration during the cleanliness test. Fibers are then difficult to measure and are therefore not adequately represented in a measurement report. The main reasons for the difficult metrological detection areThe number of fibers cannot be determined automatically due to the fact that some fibers lie on top of each other in layers.

The true length of the fiber differs greatly from the longest extension.

The fiber width cannot be determined automatically with the currently available algorithms due to the filigree entanglement.

Influence

Since there is no clean air in conventional production environments, fibers and lint can only be influenced by manufacturers or suppliers to a limited extent. This may also be due to climatic conditions that do not allow for closed rooms (windows, doors).Damage potential

In functional applications in the electronics sector, the damage potential of individual fibers and lint is significantly lower than the particle load caused by large metallic particles. However, an increased total quantity of fibers can be functionally critical, for example by clogging narrow hydraulic cross-sections. To describe such total fiber loads, the new VDA 19.1 (2025) now also defines the measurement of the "total fiber length" as the sum of the stretched lengths of all fibers.

Design of the production environment

When considering airborne particles, it is generally advisable to take the cleanliness levels (SaS) described in VDA 19.2 "Technical cleanliness in assembly" into account when designing the production environment. The recommended cleanliness level can be determined using the flight capability diagram, taking into account the cleanliness requirements or the permissible particle size and the particle materials. Fibrous particles are also taken into account.

If only compact particles are considered, i.e. without fibers and lint, the design point is at the intersection of the cleanroom and cleanroom. If fibrous particles were neglected, the planning of the production environment would have to be based on cleanliness level 2 (cleanroom) and the detailed design would have to take into account the recommendations of the VDA guideline for SaS2 (cleanroom), whereby elements of SaS3 (cleanroom) would have to be included.

When considering fibers and lint, however, elements of SaS3 (cleanroom) can play a much more important role.

Room concepts

Cleanliness rooms (SaS2)

Cleanliness rooms are controlled production environments that are specially designed to prevent contamination by larger particles. Compared to cleanrooms, cleanliness rooms have less stringent requirements for air purity and particle sizes. However, they are still crucial for the production of sensitive components and parts as they ensure quality by reducing dust and dirt.

Advantages of cleanliness rooms:

Cost efficiency: Cleanliness rooms are less expensive to construct and operate than cleanrooms, as they have lower requirements for air filtration and air conditioning.

Flexibility: Cleanliness rooms can be flexibly adapted to the specific requirements of production, often using modular system walls or the conversion of existing rooms.

Protection against larger particles: Cleanliness rooms prevent contamination by larger particles (50-1000 micrometers), which can impair the quality of the products.

Cleanroom concepts (SaS3)

Implementing cleanrooms is a proven method for minimizing contamination, especially from fibers. Cleanrooms provide controlled environments with stringent air filtration systems that reduce the number of particles, including fibers, in the air. Airborne particles, including dust, fibers and microorganisms, can enter the manufacturing environment through air circulation. These particles can come from the outside air, from employees or from materials.

Material selection and handling

The selection of suitable materials and their correct handling are crucial to avoid contamination with fibers. Here are some important aspects:

Selection of suitable materials

Fiber-free materials: Materials should be selected that do not release fibers. Examples of this are certain plastics, metals and coated materials.

Material compatibility: The materials must be compatible with the production processes and the end products in order to avoid chemical reactions or material degradation.

Quality certificates: Materials supplied by suppliers with appropriate quality certificates should be used to ensure purity and quality.

Handling and storage

Clean storage conditions: Materials should be stored in clean, controlled environments to avoid contamination. Closed containers and packaging are an advantage here.

Transportation methods: Special transportation methods should be used to move materials safely and cleanly. This may include the use of covered trolleys or special packaging.

Regular inspections: Regular inspections of storage and transportation conditions should be carried out to ensure that no contamination occurs.

Employee training

Handling techniques: Mitarbeiter sollten in den besten Praktiken zur Handhabung von Materialien geschult werden, um die Freisetzung von Fasern zu minimieren.

Cleanliness measures: Employees should be made aware of the importance of cleanliness measures, such as wearing protective clothing and avoiding direct contact with the materials.

Examples of suitable materials

Plastics: Polypropylene (PP), polyethylene (PE) and polyvinyl chloride (PVC) are examples of plastics that generally do not release fibers.

Metals: Stainless steel and aluminum are resistant and do not release fibers if they are treated correctly.

Beschichtete Materialien: Materials with special coatings that prevent the release of particles and fibers.

By carefully selecting and handling the materials, the risk of contamination with fibers can be significantly reduced, resulting in higher quality and reliability of the automotive components produced.

Process optimization

Optimizing production processes can also help to reduce contamination. This includes the use of closed systems, minimizing manual intervention and regular maintenance and cleaning of machinery. Production systems and machines can cause contamination due to wear and tear, inadequate maintenance or improper cleaning. This can lead to the release of particles and fibers.

Technical measures to prevent contamination

Air filtration

High-efficiency air filter systems (HEPA filters) are able to remove even the smallest particles and fibers from the air. These systems should be regularly maintained and checked to ensure their effectiveness.

Monitoring and control

Continuous monitoring of air quality and surface cleanliness is crucial. This can be done by using particle counters and other monitoring devices. Regular audits and inspections help to identify and eliminate potential sources of contamination at an early stage.

Organizational measures

Training and sensibilization

Employees should receive regular training and be made aware of the importance of contamination control. This includes training on best practice in the handling of materials and cleaning of work areas.

Documentation and tracking

Comprehensive documentation of all processes and measures for contamination control is essential. This enables seamless tracking and helps to identify and eliminate weak points in the system.

Role of employees

Training and sensibilization

Employees must be regularly trained to understand and apply best practices to prevent contamination. This includes:

Handling of materials: Proper material handling and storage techniques to minimize the release of fibers.

Cleaning and maintenance: Procedures for effective cleaning and maintenance of work areas and machines.

Compliance with protocols

Employees must adhere to strict protocols and procedures specifically designed to prevent contamination. These include:

Wearing protective clothing: Use of special clothing that does not release fibers.

Access controls: Limit access to sensitive areas to reduce the risk of contamination.

Monitoring and control

Employees play an active role in monitoring the production environment. This includes:

Regular inspections: Carrying out inspections and audits to identify potential sources of contamination.

Documentation: Careful documentation of all measures and observations to ensure seamless tracking.

Continuous improvement

Employees should be encouraged to make suggestions for improving contamination control. This promotes a culture of continuous improvement and innovation.

Conclusion

Avoiding contamination with fibres in the production of functional automotive components requires a holistic approach that includes both technical and organizational measures. The quality and reliability of products can be ensured by implementing suitable cleanroom and cleanroom concepts, carefully selecting and handling materials, optimizing production processes and continuously monitoring and training employees. A comprehensive contamination control strategy is essential to meet the stringent requirements of the automotive industry and ensure the safety and functionality of components.

Newsletter registration