Determination of organic, filmic contamination of surfaces as a sum parameter

The determination of organic, filmic contamination on surfaces is an important aspect in many industries, especially in manufacturing and quality assurance. Filmic or chemical residues can significantly impair the functionality of components and make further processing steps more difficult. Film residues lead to complications, particularly in painting and bonding processes and in areas where optical properties are essential. This affects both the technical application and the aesthetics. This white paper compares three different analysis methods for determining these impurities.

- Evaporator gravimetry

Gravimetric determination of non-vaporizable, soluble residues (NVR) after solvent-assisted extraction and subsequent removal of the extraction medium under reduced pressure.

- THC (total hydrocarbon content)

Determination of the total content of hydrocarbon compounds using gas chromatography/mass spectrometry (GC/MS)

AGREE® method

Determination of gravimetrically detectable non-volatile residues at very low sample volumes (µNVR) using a nanobalance (QCM), known as the AGREE® method (AGREE = Analysis of Gravimetrically Detectable Residues by Efficient Extraction).

1. Evaporator gravimetry

Method

In the gravimetric determination of non-volatile residues, the surface to be examined is extracted with a suitable solvent. The extraction is usually carried out on the entire surface of the component. This test method is therefore considered an integral method.

A commonly used solvent is ethanol, whose purity (absence of NVR components) is ensured by prior distillation. The extract is then filtered to remove insoluble particles. The solvent is then removed using a rotary evaporator (Figure 1). The remaining non-evaporable residues are weighed.

Detection limit

Ideally, the detection limit is only determined by the resolution and precision of the balance. However, it is often limited by the tare mass of the glass flask used relative to the low mass of the analyte.

Costs

The costs for determination using evaporator gravimetry can vary, but are typically in the range of 300 and 500 euros per analysis. The costs depend on the number of samples and the complexity of the preparation.

| Advanages | Disadvantages |

| ➕ Low complexity of the analysis process | ➖ High time expenditure |

| ➕ For all compounds with low vapor pressure | ➖ Requires purified solvents and special equipment |

| ➖ Rather unsuitable for low levels of soiling |

2. THC (Total-Hydrocarbon-Content)

Method

Analogous to the gravimetric determination of the NVR, the filmic residues are first extracted with a volatile organic solvent. A range of solvents can be used for this, which can differ greatly in their solvation capacity. These are frequently used: Short-chain alkanes C5-C7 (pentane, hexane, heptane), ethers (diethyl ether, tert-butyl methyl ether, tetrahydrofuran = THF), ketones (acetone, methyl ethyl ketone = MEK), esters (ethyl acetate, butyl acetate), dichloromethane, alcohols C1-C3 (methanol, ethanol, iso-propanol). The selection should always be based on aspects of occupational safety and material compatibility.

The total content of hydrocarbon compounds (THC) is determined using gas chromatography (GC) coupled with mass spectrometry (MS). The compounds are separated on the basis of their chemical properties, the individual “molecule packages” are ionized and detected on the basis of their specific mass-to-charge ratio. Prior calibration with a hydrocarbon mixture of known concentration enables precise semi-quantification of the substances to be determined.

As the mass-to-charge ratio is an excellent characteristic of the chemical composition, the GC/MS method is ideal for characterizing the underlying substances with the aid of a comparison with reference substances or a database. This makes it particularly easy to investigate the causes of chemical contamination.

Detection limit

The detection limit of this method is about 0.1 ppm.

Costs

The costs for a THC determination are usually between 300 and 500 euros per analysis. By increasing the test lot size, the financial impact of the calibration can be minimized very well as this only has to be carried out once per series of measurements. This means that the total costs are mainly determined by the costs for extracting the test parts.

| Advantages | Disadvantages |

| ➕ High sensitivity and linearity | ➖ High costs with small sample lot size |

| ➕ High sample throughput due to automation with autosampler | ➖ Requires special equipment and trained specialists |

| ➕ Suitable for continuous measurements | ➖ Time-consuming: Creation of references and measurement of blanks, references and the actual samples |

| ➕ Characterization through comparison with references / databases | |

| ➕ Costs scale with the number of samples per measurement series |

3. AGREE® methodVerfahren.

Determination of non-volatile residues (µNVR) in the sub-µg range using a nanobalance (QCM)

Method

This is a new method for testing the cleanliness of chemical or filmic residues on component surfaces that has been specially developed to meet these particular requirements. In the AdhäSa (adhesive cleanliness) industry association, this method was standardized for this application under the technical leadership of Fraunhofer IPA and described in the VDI 2083 Sheet 23 guideline from 2022. This guideline forms the basis for the accreditation of the process at CleanControlling. The AGREE® method is therefore the only standardized test method specifically for this application and thus the optimal basis for quality agreements in the customer-supplier relationship.

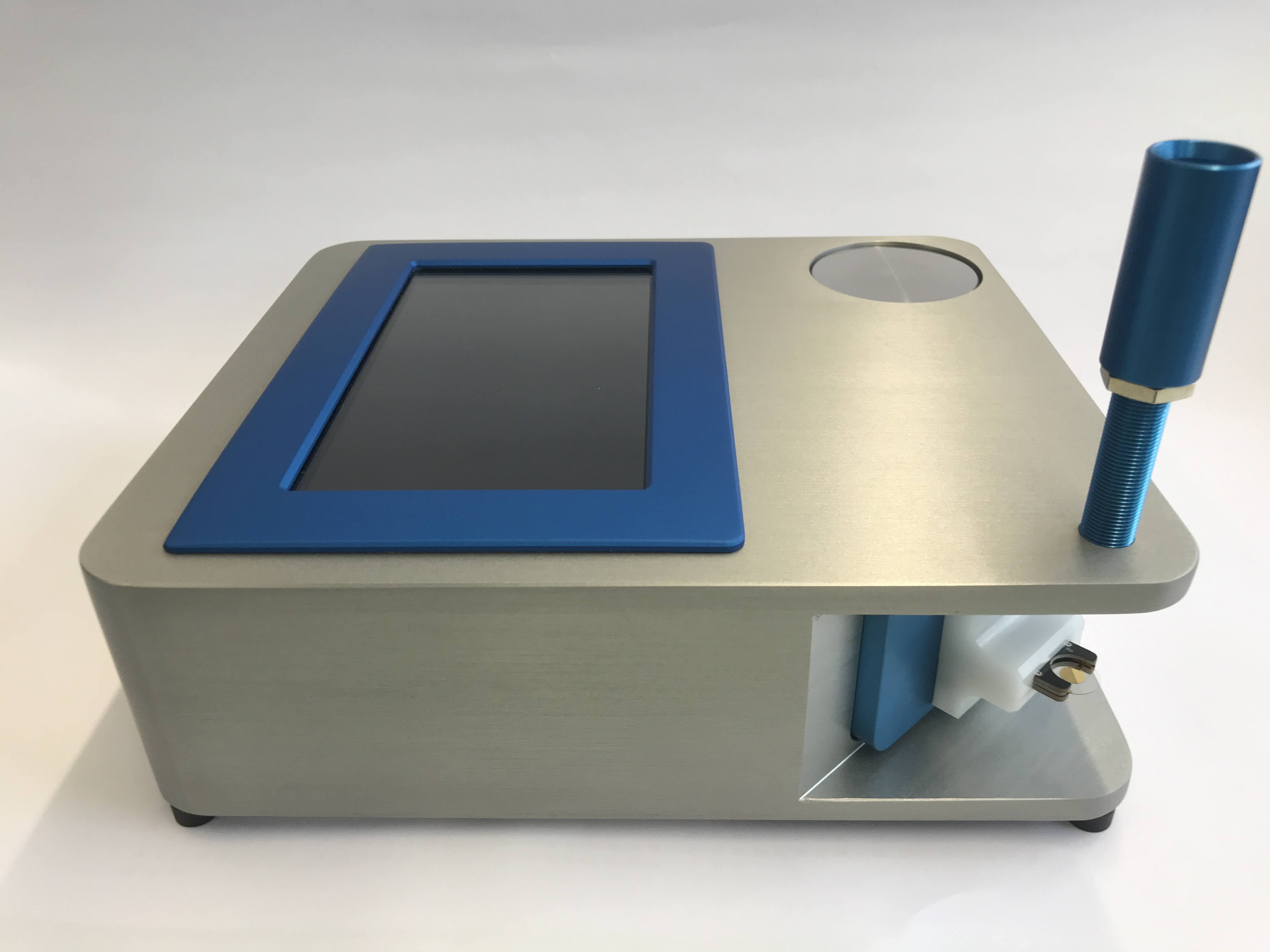

Similar to the method described in section 1 and 2, the AGREE® method also involves extracting the filmy residue from the test specimen using a suitable solvent. However, to determine the mass of the NVR, the AGREE® method uses an analyzer (Figure 2) with a quartz crystal microbalance (QCM), which measures the moment of inertia of the forming film instead of the weight. This also enables the determination of very small masses of only a few tens of nanograms (10 ng = 1/100,000 mg).

The optimum operating window for weighing is between 0.1 - 1 µg, so that only a partial volume (aliquot) of the extract is ever used for weighing. By adjusting the extraction volume or concentration, AGREE® allows the direct analysis of only slightly contaminated parts (AGREE® finds a fingerprint) as well as the sampling of small surfaces (a few 10 mm² are sufficient). The latter in particular enables a variety of spatially resolved extraction methods. This allows different sub-areas to be examined separately in order to draw more precise conclusions regarding the origin and spread of filmic contamination.

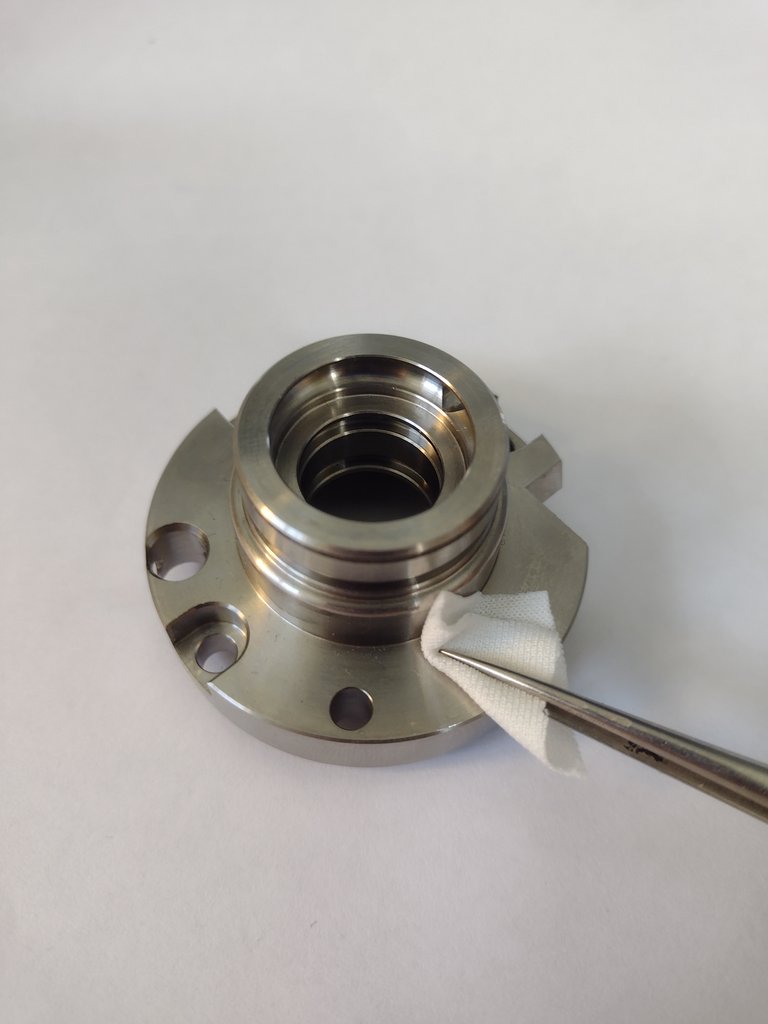

The underlying guideline VDI 2083 Sheet 23 defines the basic framework conditions and qualifies a range of possible extraction methods (Figure 3). The VDI NVR classes defined in VDI 2083 Sheet 23 (Table 1) enable a simple and meaningful classification of the extent of film contamination and the definition of limit values.

Detection limit

The detection limit of this method is approximately 0.01 µg/cm².

Costs

The costs for µNVR determination using AGREE® are typically between 200 and 350 euros per analysis. They are primarily dependent on the complexity of the extraction.

| Advantages | Disadvantages |

| ➕ High sensitivity and low detection limit | ➖ Requires special equipment and calibration |

| ➕ Minimal solvent consumption | ➖ Limited applicability with less volatile extraction media |

| ➕ Wide range of (spatially resolving) extraction methods possible | |

| ➕ Normatively described in VDI 2083 Sheet 23 | |

The methods in comparison

| Method | Advantages | Disadvantages | Detection limit | Costs per Analysis |

| Evaporator gravimetry |

|

| Depends on precision and resolution of the analytical balance | 300-500 € |

| THC (Total-Hydrocarbon Content) |

|

| 0,1 ppm | 300-500 € |

| AGREE® method |

|

| 0,01 µg/cm² | 200-350 € |

Conclusion

The choice of the appropriate analytical method depends on the specific requirements and conditions of the respective application.

The gravimetric determination of NVR is the most robust and simplest method, but it is time-consuming and unsuitable for low levels of contamination.

The AGREE® method, on the other hand, is particularly suitable for applications with minimal solvent consumption, small sample quantities and small test areas. It was developed specifically for the special requirements of testing the cleanliness of chemical or film residues on component surfaces and is described in the VDI 2083 Part 23 guideline. This guideline forms the basis for the accreditation of the procedure at CleanControlling. The AGREE method is therefore the only standardized and accredited test method specifically for this application and forms the optimal basis for quality agreements in the customer-supplier relationship.

The THC determination is ideally suited for special issues where particularly sharp detection limits are required and where the characterization of the underlying chemical compounds is also highly relevant.

Newsletter registration