How does a CT analysis work and what are the results?

Computed tomography (CT) is a modern imaging method used in materials science for the non-destructive testing and analysis of materials. This technique can be used to create detailed 3D images of the internal structure of a material without damaging it. In addition to assessing material quality, this method can also be used to visualize and evaluate homogeneity, for example.

How CT analysis works

CT analysis is based on the use of X-rays, which are sent through the material to be examined. A detector records the rays passing through the material and creates sectional images. A computer then reconstructs these sectional images into a three-dimensional image.

The CT analysis procedure

In preparation for the test, the necessary parameters for the component to be examined can be set in a pre-scan, as can the approximate scan time. The sample is then carefully positioned to ensure uniform transmission.

Acquisition of the data: The CT scanner rotates around the sample and creates X-ray images from different angles.

Image reconstruction: Software compiles the captured images into a 3D model.

Analysis: The 3D model is analyzed to obtain information about the internal structure, material defects, porosity and other properties.

Results of a CT analysis

The results of a CT analysis are diverse and offer in-depth insights into the material properties:

Three-dimensional representation: CT analysis provides detailed 3D images of the internal structure of the material, enabling visual inspection.

Material defects and inhomogeneities: Cracks, pores, inclusions and other defects can be precisely localized and quantified.

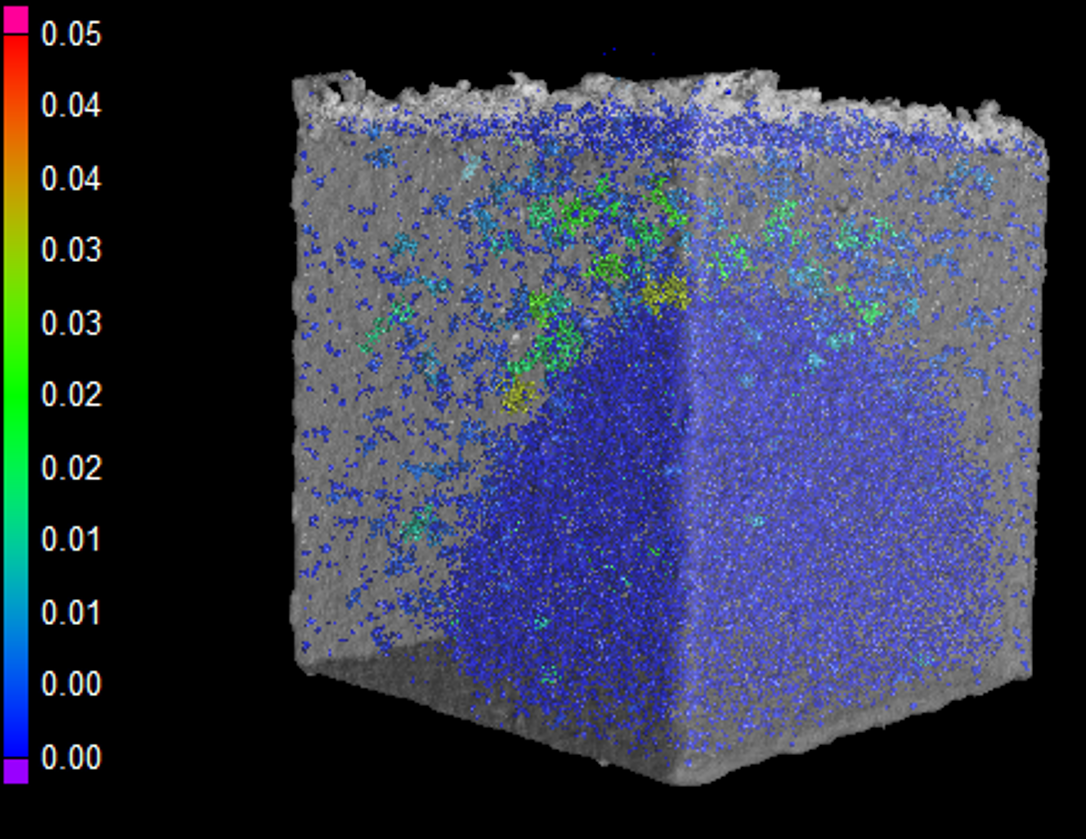

Porosity analysis: The distribution and size of pores in the material can be determined. This is of great importance for the evaluation of material quality.

Structural analysis: The analysis of the microstructure of the material helps to understand its mechanical properties and behavior under load.

Comparison with target values: The data obtained can be compared with the target values to identify deviations and support quality assurance.

Applications in materials science

CT analysis is used in various areas of materials science:

Metallurgy: Investigation of casting defects, crack formation and material homogeneity in metals.

Plastics technology: Analysis of fiber reinforcements and defects in composite materials.

Ceramics: Evaluation of the density and homogeneity of ceramic materials.

Electronics: Inspection of solder joints and internal structures of electronic components.

Conclusion

Computed tomography is an indispensable tool in materials science as it provides detailed insights into the inner structure of materials. Through non-destructive testing and the creation of three-dimensional images, CT analysis makes a significant contribution to quality assurance and material development. Due to the device specifications, however, CT analysis is limited in terms of the dimensions of the components to be tested.

Newsletter registration