Bioburden validation - basics, methodology and significance

Bioburden determination is a central procedure for the microbiological quality control of medical devices. It is used to determine the total number of viable microorganisms (bacteria, fungi) on a product. A valid test method is essential to ensure reliable and reproducible results - especially in the context of regulatory requirements such as the MDR (EU 2017/745) and GLP.

Why is a validation of the bioburden determination necessary?

The efficiency of the bioburden determination depends heavily on the geometry of the test specimen and the material properties of the test specimen. Different surfaces can bind microorganisms to different degrees. Validation of the method ensures that the chosen extraction method is suitable for the specific product.

Why are three test specimens used for validation?

The use of three test specimens is required in accordance with DIN EN ISO 11737-1 in order to prove the reproducibility and robustness of the method. This number enables a statistically relevant statement to be made about the recovery rate and reduces the risk of random errors. The test specimens are inoculated under sterile conditions with a defined quantity of a known microorganism and then analyzed.

When is the validation carried out?

Validation should be carried out before the actual bioburden analysis. This ensures that the method is suitable for the product in question and that the results of the subsequent routine tests can be interpreted correctly. The validation also provides a correction factor that is taken into account in future analyses for the specific product.

How is validation carried out?

The validation of the bioburden determination takes place in several steps:

1. Inoculation

Three identical test specimens are inoculated with a defined quantity of a known test organism (e.g. Bacillus subtilis). When distributing the inoculum on the product, different surface textures at different points on the product must be taken into account, as well as areas that are difficult to access, such as holes or fluting.

2. Extraction

The microorganisms are removed from the surface of the test specimens by extraction with a sterile solution. Shaking ensures that all surfaces of the test specimen are constantly rinsed.

3. Filtration

The extraction medium is filtered under sterile conditions through a sterile membrane (0.22 µm pore size). The membrane is then transferred to a suitable culture medium.

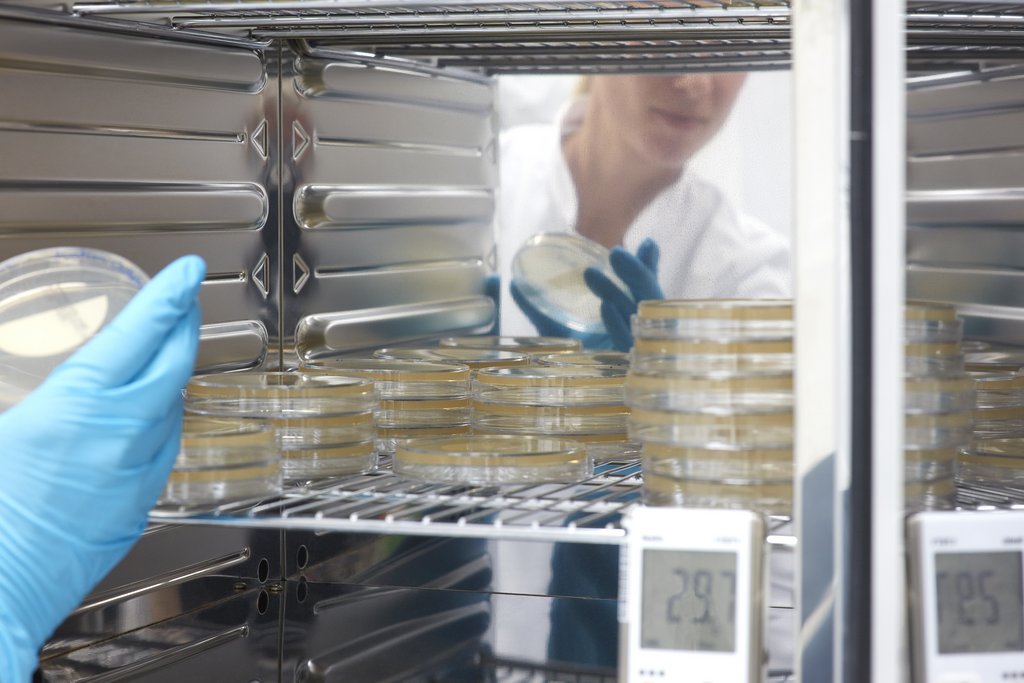

4. Incubation

The membrane filters are applied sterile to culture media (e.g. tryptic soy agar) and incubated under the following conditions:

- Temperature: 30-35 °C for aerobic bacteria

- Duration: 5 to 7 days

5. Evaluation

After incubation is complete, the colony-forming units (CFU) are counted. The recovery rate is determined by comparing the number of CFU recovered with the amount originally applied. Based on this recovery rate, a correction factor is calculated which is applied to all subsequent bioburden analyses of the product in question.

How much time does bioburden validation take?

The entire bioburden validation with all the necessary steps takes up to 9 days, plus the administrative preparations for the test. The processing times for the individual steps are shown in the table.

| Work step | Duration |

| Preparation & inoculation | approx. 3 hours |

| Extraction & Filtration | approx. 3 hours |

| Incubation | up to 7 days (depending on the organism) |

| Evaluation & documentation | approx. 1 day |

Conclusion

Bioburden validation is an essential part of microbiological quality control. It ensures that the selected method is suitable for the respective product and provides the basis for the interpretation of the subsequent bioburden results. The use of three test specimens and the performance of validation prior to routine analysis are important requirements in accordance with DIN EN ISO 11737-1.

Newsletter registration