Suction extraction according to the new VDA 19.1

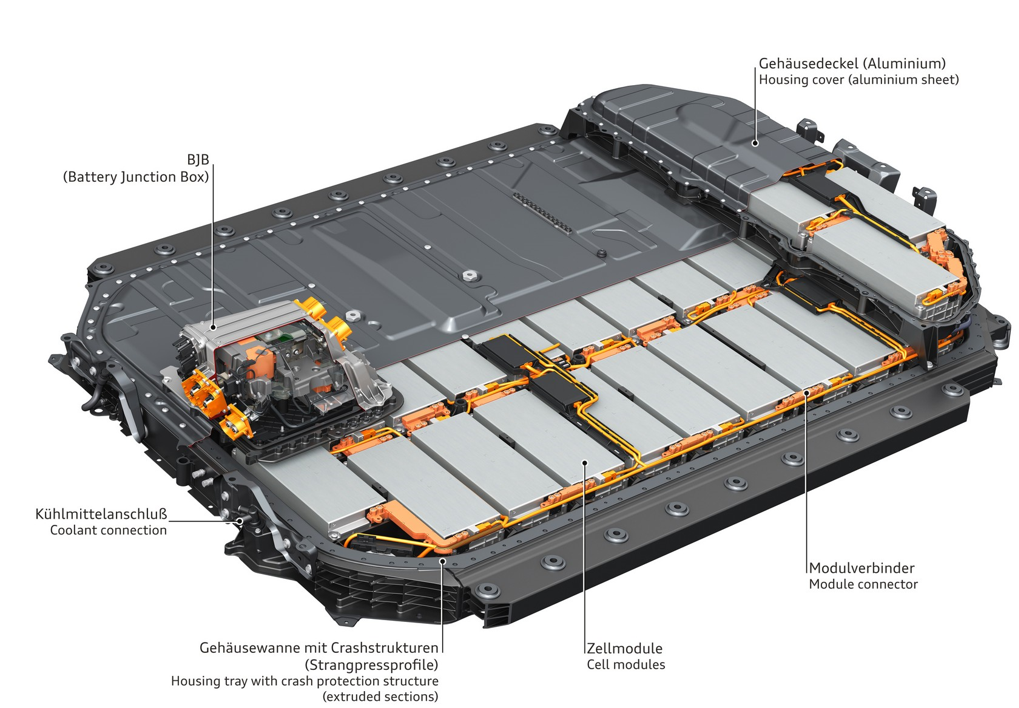

The requirements for the technical cleanliness of components are constantly increasing – especially in the field of electromobility. The revised VDA 19.1 standardizes additional test methods for determining particulate contamination that have been adapted to the new requirements. Although classic wet extraction is established for many applications, it has its limitations when it comes to certain components. In such cases, suction extraction offers an innovative, dry, and non-destructive alternative.

What is suction extraction?

In suction extraction, a method for determining technical cleanliness, particles are removed from the component surface using a defined air flow and deposited on analysis filters. This method is particularly suitable for components that must not come into contact with liquids or for which wet extraction is difficult due to their geometry or size.

Advantages over wet extraction:

- No risk of liquid damage

- Mobile and flexible use

- Shorter testing times and lower logistical costs

Suitable component types

Suction extraction is recommended for:

- Large components such as battery modules and HV systems

- Electronic components (printed circuit boards, connectors)

- Cable harnesses

- Styrodur containers

- Workpiece carriers and load carriers (KLT)

- Components in the process environment, e.g., between assembly steps

- Components in incoming goods inspection

These types of components benefit from dry, non-destructive extraction, which enables fast and reproducible analysis.

Extraction systems and components

Modern suction extraction solutions consist of several elements:

- Particle suction extraction systems, e.g.:

- C|PS³flex: Compact, mobile system for flexible testing

- C|PS³apex: Complete system with digital control for reproducible processes

- Extraction nozzles: Brush nozzle, flat nozzle, special nozzles for complex geometries

- Particle separation units: Cyclone unit for high particle loads, filter unit for direct analysis

- Equipment and accessories: Volume flow monitoring, analysis filter, suspension unit, wet cleaning system, ESD protection

Standards and methods

With the revision of VDA 19.1 (2025, yellow band), suction extraction has been standardized as a new extraction method. The methods for qualifying test parameters, analysis filtration, and microscopic evaluation are fully compliant with the current VDA 19.1 (2015) and ISO 16232. In addition, various factory-specific, component-related test specifications from well-known manufacturers are already in use.

To qualify the extraction parameters, the decay measurement described in the standard is used to ensure efficiency and reproducibility.

Advantages of suction extraction

- Non-destructive and dry

- Mobile and flexible in use

- Low time and logistics costs

- Reproducible results

- Ideal for sensitive or large-area components

Conclusion

Suction extraction according to VDA 19.1 (2025) is a forward-looking method for components that are not suitable for wet extraction. It enables efficient, standard-compliant, and economical testing of technical cleanliness—especially in areas where sensitive or large-format components are processed.

Newsletter registration