Monitoring technical cleanliness – What the new VDA 19.1 (2025) changes

With the revision of VDA 19.1 (2025), process-oriented monitoring of technical cleanliness is coming into focus for the first time, alongside classic limit value testing. The background to this is the increasing safety-critical requirements of modern technologies – from electromobility and driver assistance systems to autonomous driving. The new framework conditions require testing methods that are fast, mobile, practical, and adaptable to trends.

Why technical cleanliness is critical to safety today

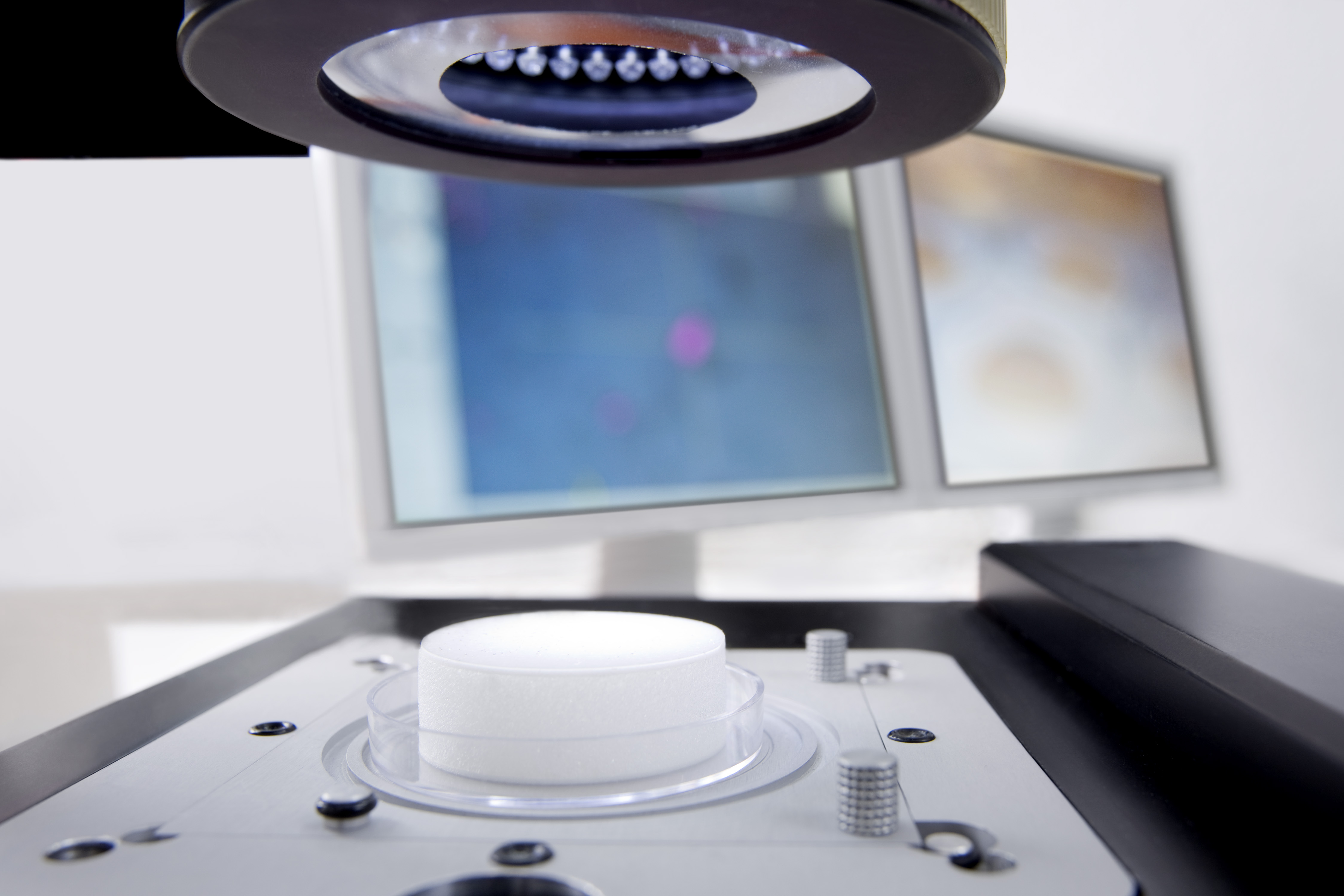

The components of modern vehicle technologies, especially in the field of e-mobility and autonomous driving, operate in highly sensitive functional areas. High-voltage systems, camera-based sensor technology, and increasingly dry manufacturing processes require cleanliness requirements that are based on critical damage mechanisms such as conductivity, hardness, or optical blockage. This means that technical cleanliness is changing from a "quality feature" to a safety-relevant drawing entry with a factual test character. At the same time, the number of large, heavy, or sensitive components for which classic laboratory analyses are hardly suitable is increasing.

Monitoring instead of just limit value testing

The new VDA 19.1 (2025) will make a clear distinction between different aspects in the future.

1. Limit value test

The standardized, VDA-compliant cleanliness test on a representative test object, which is primarily used for product approval and specification verification.

2. Process monitoring

Production-accompanying tests that must be frequent, fast, and trend-capable.

The following are permitted:

- Partial area-related tests,

- Component-related or process-related measuring points.

Non-VDA-compliant methods are also permissible, provided they are reproducible and used consistently. Dry extraction methods in particular, such as suction extraction, stamping, or sedimentation, significantly expand the range of suitable analysis methods.

Methods in particle monitoring – an overview

All monitoring methods basically consist of two steps: extraction and analysis.

1. Rinsing extraction (liquid) + microscopy

✔ VDA-compliant, highly informative

✘ slow, laboratory-based, destructive – therefore not process-oriented

2. Suction extraction (dry) + microscopy

✔ mobile and non-destructive

✔ VDA compliant

✘ Analysis times in the laboratory

3. Suction extraction + direct optical inspection

✔ immediate mobile results

✔ ideal for trend and process monitoring

✘ Limited sample carrier area, not suitable for specification testing

4. Stamp extraction + microscopy or light optics

✔ component-oriented, non-destructive

✔ particularly suitable for source analysis

✘ area-specific, not mobile depending on evaluation

5. Sedimentation (particle traps)

✔ Ideal for monitoring the assembly environment

✘ time-consuming (with microscopy)

✔ significantly faster with light optics

6. Suction extraction + real-time particle counter

✔ Immediate results, ideal for shift alarms

✔ mobile extraction

✘ Particle measurement not fully VDA-compliant → not suitable for specification verification

Brief overview: When to use which method?

Product approval / Specification verification

→ VDA-compliant cleanliness test (including material determination with SEM/EDX or IR, if necessary).

Process control / Trend monitoring

→ Dry extractions + mobile light optics or real-time counters.

Root cause analysis / Environmental assessment

→ Sedimentation methods and component-close stamping.

Important: Ensure reproducibility, document start parameters, visualize trends.

VDA 19.1 & ISO 16232 – what's next?

The contents of the new VDA 19.1 are to be transferred to ISO 16232 as before; work on this is already underway. Anyone who aligns themselves with the Yellow/Red Band 2025 is well prepared for the upcoming harmonization.

Conclusion

The revision of VDA 19.1 makes it clear that technical cleanliness today is an active control loop and not a final laboratory test. With the help of mobile, fast, and trend-capable monitoring methods, processes can be stabilized, risks minimized, and specification violations detected at an early stage. The new freedoms, in particular the permissibility of non-VDA-compliant methods for monitoring, open up completely new possibilities for manufacturing companies.

Newsletter registration