Comparison of C|PS³mobile versus C|PS³apex suction extraction systems

The importance of suction extraction

The change in mobility and general technological developments in the automotive industry have left their mark on existing standards. The requirements for technical cleanliness have also increased due to the shift towards e-mobility, assistance systems and autonomous driving as well as general trends. The third edition of VDA 19.1, which is expected to be published in November 2025, will therefore expand dry extraction to include (brush) suction extraction.

Suction extraction is becoming increasingly important as an alternative to traditional liquid extraction, as it is more advantageous for certain applications and component types - for example in e-mobility. It is an application-oriented, non-destructive extraction process that is particularly suitable for testing electronic components, battery components and complex HV systems. Suction extraction also enables test parts to be sampled directly in the production line. Due to its mobile application, suction extraction is also suitable for testing the cleanliness of the process environment.

CleanControlling has developed the two variants C|PS²mobile and C|PS³apexto cover this variety of applications with the corresponding systems. The following comparison is intended to help you find the right system for your particular application.

You can find out more about suction extraction and suction extraction systems here...

C|PS²mobile

The lightweight and compact system for mobile use

The proven compact system C|PS²mobile is characterized by its flexible, modular and compact design. The individual system modules can be combined as required or used separately. This facilitates transportation and access to confined areas, for example for particle extraction in process environments or in production plants for particle monitoring.

The individual modules can be easily stowed in the trunk of a car and are therefore also suitable for flexible use at other production sites.

The C|PS² compact system consists of the extraction module, the suction unit and the practical accessory module with all the accessories for extraction, analysis and cleaning in separate drawers.

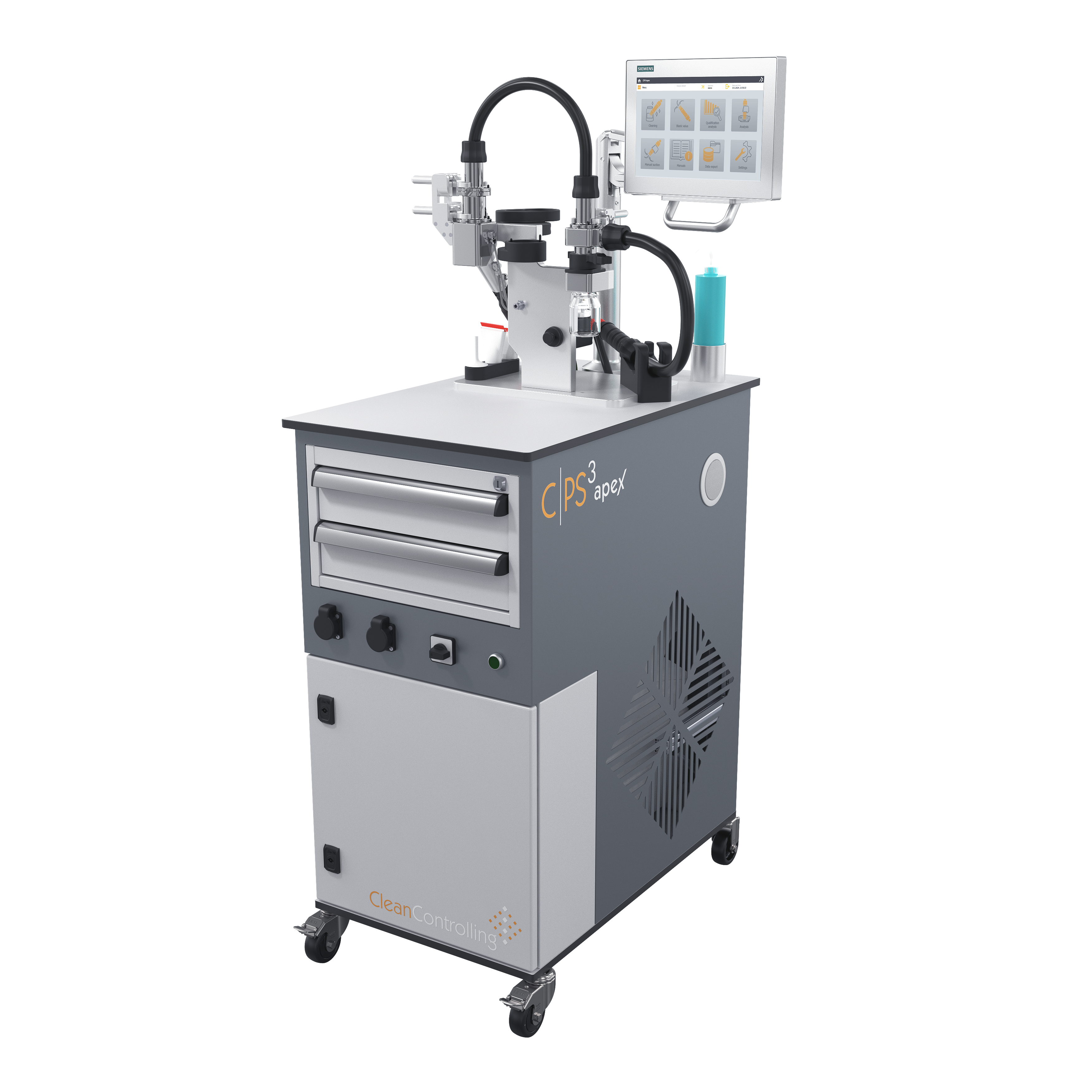

C|PS³apex

The ergonomic complete system with digital control for reliable user guidance.

C|PS³apex is a consistent new development based on all the user experience gained in recent years with the C|PS² particle suction extraction system.

In addition to the complete, ergonomic redesign of the structural layout, the user-friendly navigation with voice prompts through the freely programmable test sequence in particular helps to ensure reproducible cleanliness tests. For this purpose, the system has a modern digital control system for storing analysis parameters and for visual support by displaying the test sequences on the screen.

Comparison of C|PS²mobile versus C|PS³apex

| Feature | C|PS²mobile | C|PS³apex |

|---|---|---|

| System type | Mobile suction extraction system | Stationary high-end suction extraction system |

| Objective | Flexible on-site inspections | Reproducible laboratory and series tests |

| Mobility | ✅ Lightweight and compact | ❌ Stationary with modular equipment |

| Control system | Manuell | Digital, storable test programs |

| User guidance | ❌ | Interactive via touch panel, voice guidance |

| Data management | ❌ | Digital, with export function and logging |

Areas of application

| Application | C|PS²mobile | C|PS³apex |

|---|---|---|

| On-site inspections | ✅ Optimally suited | ❌ Not intended |

| Laboratory analysis | ⚠️ Possible to a limited extent | ✅ Ideally suited |

| Series tests | ❌ Not suitable | ✅ Highly programmable, optimum reproducibility |

| ESD areas / ESD components | ❌ Not suitable, no ESD protection | ✅ Fully integrated ESD protection |

| Training & demonstrations | ✅ Mobile use | ✅ Ideal with user guidance |

Target group recommendation

| User profile | Recommended system |

|---|---|

| Quality inspector in production | C|PS²mobile |

| Cleanliness expert with changing work locations | C|PS²mobile |

| Quality manager in the cleanliness laboratory | C|PS³apex |

| Production manager with series production | C|PS³apex |

| Production managers in ESD areas | C|PS³apex |

| Companies with high documentation and reproducibility requirements | C|PS³apex |

Application scenarios

Scenario 1: Production line with changing components

User Story:

As a quality inspector in production, I would like to carry out cleanliness checks directly on the line so that I can react immediately to any anomalies without having to take components to the laboratory.

| Recommended system | Reason |

| ✅ C|PS²mobile | ✔ Mobile and easy to transport ✔ Quick manual operation ✔ Ideal for flexible on-site testing |

Scenario 2: Validation of new cleaning processes in the laboratory

User Story:

As a cleanliness expert in the laboratory, I would like to carry out reproducible tests with documented parameters to validate the effectiveness of new cleaning processes in accordance with VDA 19.1.

| Recommended system | Reason |

| ✅ C|PS³apex | ✔ Digital control with storable test programs ✔ Ideal for laboratory analyses and series testing ✔ Integrated data management for documentation and traceability |

Scenario 3: Audit at the supplier

User Story:

As an external auditor, I would like to carry out a quick cleanliness inspection at the supplier's premises in accordance with VDA 19.1 in order to check compliance with the agreed limit values.

| Recommended system: | Reason: |

| ✅ C|PS²mobile | ✔ Mobility and easy handling ✔ No infrastructure required on site ✔ Ideal for ad hoc tests |

Scenario 4: Series testing in e-mobility production

User Story:

In my role as production manager in battery production, I would like to carry out regular cleanliness tests on ESD-sensitive components to ensure process reliability.

| Recommended system: | Reason: |

| ✅ C|PS³apex | ✔ Integrated ESD protection ✔ Automated test sequences ✔ Ideal for series testing with high reproducibility |

Scenario 5: Training new employees in the cleanliness laboratory

User Story:

As a training manager, I would like to instruct new employees in cleanliness testing and provide them with guided, comprehensible operation.

| Recommended system: | Reason: |

| ✅ C|PS³apex | ✔ Interactive Benutzerführung mit Touchpanel ✔ Sprachunterstützung ✔ Ideal for structured Schulungsszenarien |

Conclusion & recommendation

C|PS²mobile is the right choice for companies that want to carry out flexible, mobile and fast cleanliness tests - e.g.directly on the production line or for external tests on site.

C|PS³apex is aimed at users with high demands on process reliability, automation and documentation, such as those typically found in laboratories or in series production.

Newsletter registration