Modern battery packs today very often contain battery cells that are manufactured, developed and produced in Asia. Battery cells are components in which complex electrochemical processes take place. Even the tiniest particulate impurities that are created during the manufacturing process and get onto the components can significantly impair the quality of the battery cells.

Metallic impurities lead to self-discharge

In particular, particles of iron (Fe) materials, for example, which are located between the anode, cathode or separator, cause the cell to self-discharge much faster, which is often illustrated by the key figure self-discharge rate. In the worst case, such functional impairments can lead to overheating and, as a result, to the destruction of the cell. This makes it all the more important to consider the aspects of technical cleanliness throughout the entire manufacturing process and to consistently focus on avoiding critical contamination.

Participants from all over the world

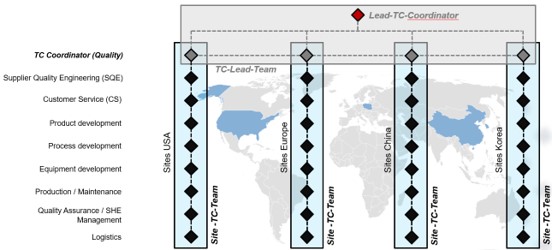

The consulting team of CleanControlling supported in several phases a leading manufacturer of battery cells and battery modules in Asia in the analysis of the current situation and the establishment of an integrated organization for technical cleanliness. For this purpose, employees from several production sites around the world came together to enable direct transfer from headquarters to the plants and to improve the understanding of particulate contamination internationally.

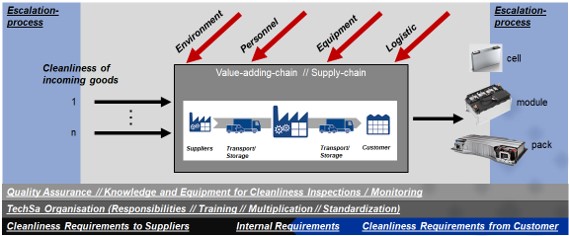

In addition to training courses on many aspects of technical cleanliness in accordance with VDA19, the entire value chain was examined and audited and recommendations for optimization were made. Especially the contents of VDA19.2 paired with the experience from more than 300 consulting projects of CleanControlling provided the optimal basis for this project.

On the basis of the detailed as-is analysis, a strategy and roadmap were jointly developed, which opens the way to a functioning, holistic and international TecSa organization. For this purpose there will be a lead team in the future, consisting of a person responsible for technical cleanliness from the headquarters and the coordinators from the plants worldwide. The topics worked out in this committee will flow into the respective plants through the coordinators.

The company will now initiate further steps towards implementation under the close supervision of CleanControlling. This will ensure optimum product quality with as little influence as possible from particulate contamination.