Technical Cleanliness - thought one step further

Organic contaminants

Recently, the damaging potential of filmic contamination (oils, greases, salts) has been increasingly recognized in the automotive industry. The primary focus here is on organic residues. These contaminations often originate from production auxiliary materials such as oils, greases, corrosion protection agents, cooling lubricants or cleaning agents. Residues of this kind very quickly lead to clear errors in the subsequent manufacturing processes. For example, such contaminations prevent complete wetting with a paint layer or significantly reduce the adhesiveness of a contact surface.

The range of relevant measuring techniques extends from simple procedures such as gravimetric detection of the residues or contact angle measurement to determine surface tension, through IR spectroscopy to characterize simple organic substances, to complex methods such as coupled gas chromatography-mass spectrometry.

Ionic contaminants

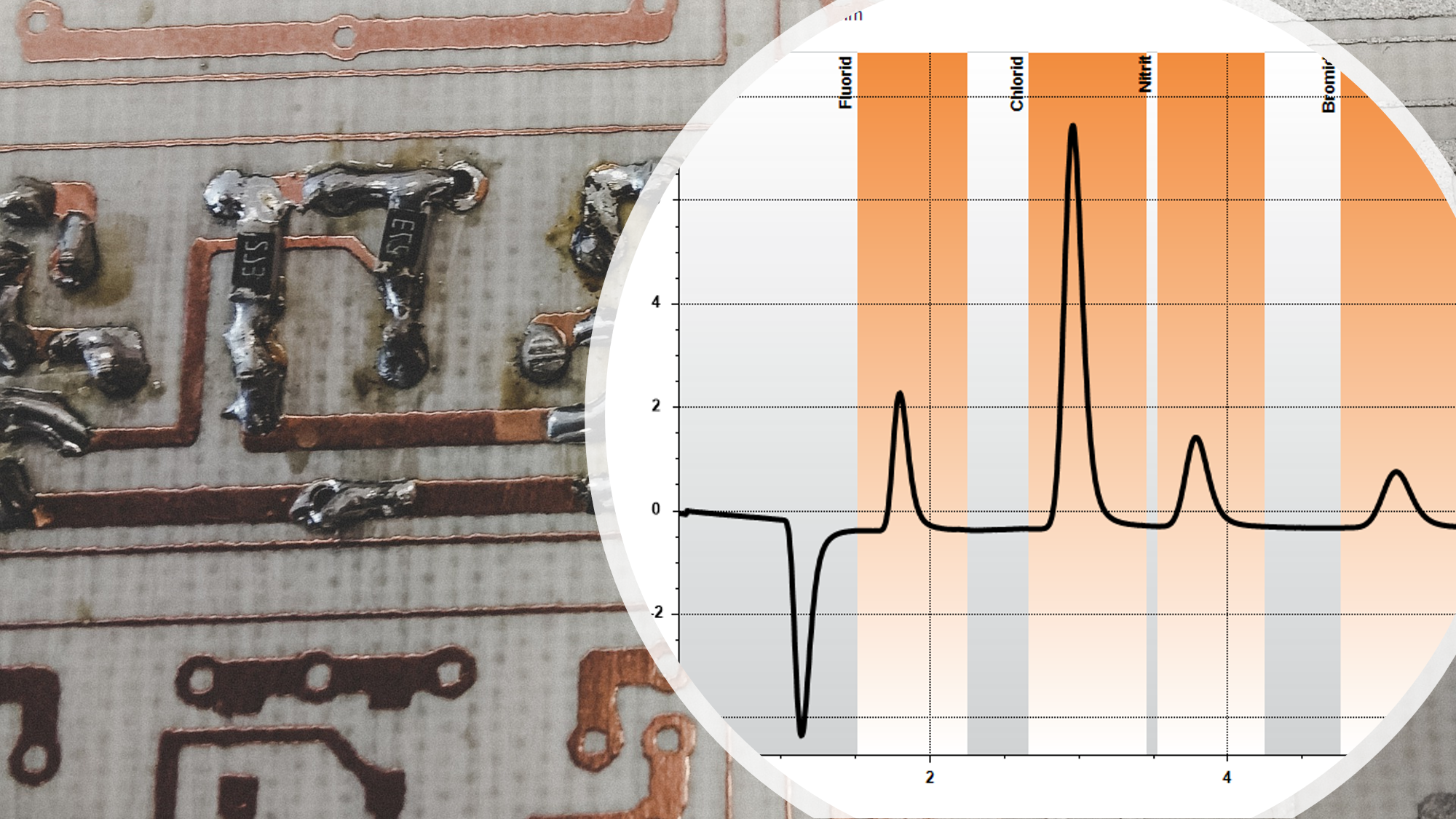

Ionic residues (salts) on components represent an important part of the filmic impurities. The increasing use of highly sensitive and compact electronics in the technically demanding automotive sector places ever stricter demands on the ionic cleanliness of such components. Here, the increasing miniaturization of electronics with very narrow contact distances meets fluctuating climatic conditions and this with a required life time of over 200,000 km. The source of ionic contamination is residues from soldering or electroplating processes.

The damage pattern includes in corrosion damage or short circuits due to the hygroscopic character of the salt residues or due to dendrite growth. The exact knowledge of the amount as well as the kind of ionic residues on the components as well as the definition of limit values is of crucial importance. Ion exchange chromatography allows the saline impurities to be characterized and quantified in the ppm range. ROSE measurement is a method for determining the conductivity of residues on electronic components.

The frequent lack of special test standards and regulations, coupled with the great chemical diversity of possible impurities, makes a universal analysis strategy, as established for particulate cleanliness in the sense of VDA 19.1 / ISO 16232, almost impossible. In order to obtain reliable and meaningful results, it is therefore essential to limit potential impurities in advance and to develop suitable analysis routines. In general, for all questions, close communication in the customer-supplier relationship is necessary in order to keep this complex area of technical cleanliness under control.

Newsletter registration

You find more information about our technical newsletter here!